Alors que le monde est aux prises avec une demande toujours croissante en matière d’économie d’énergie, Le câble de traçage thermique autorégulant apparaît comme une solution sur mesure unique.

Câbles chauffants autorégulants, également appelés câbles chauffants autolimitants, sont des composants de pointe en matière de gestion de la température. Leur mécanisme opérationnel révolutionnaire leur permet de « s’autoréguler », adjusting their heat output in response to their immediate environment.

| Taper | Pouvoir (W/M 10℃) | Max maintain temp(℃) | Max. exposure temp(℃) | Min. installation temp(℃) | Max. length of single power supply |

| Low temperature series | 10,15,25,35 | 65℃±5℃ | 105℃ | -60℃ | 7*0.5 100meters; 19*0.32 120meters. |

| Medium temperature series | 35,45,50,60 | 105 ℃ ± 5 ℃ | 135℃ | -40℃ | 7*0.5 100meters; 19*0.32 120meters |

| High temperature series | 35,50,60 | 135 ℃ ± 5 ℃ | 155℃ | -30℃ | 7*0.5 100meters; 19*0.32 120meters |

This temperature-sensitive adjustment takes place as the heating element is fused with a semi-conductive polymer, creating a complex yet efficient relationship. When the ambient temperature plummets, the polymer contracts, enhancing electrical conductivity, which in turn increases heat output. Inversement, as temperatures soar, the polymer expands, decreasing electrical conductivity, and effectively reducing the heat output.

The primary advantage of such adaptability is the remarkable energy efficiency it provides. By adjusting its own energy consumption based on environmental temperature, wasteful energy usage is consigned to history.

Beyond energy conservation, self regulating cable offers a significant safety advantage. Traditional heating cables carry the risk of overheating, potentially leading to disastrous accidents. Cependant, the self-monitoring capabilities of these innovative cables virtually eradicate such risks, ensuring operational safety even in potentially volatile environments.

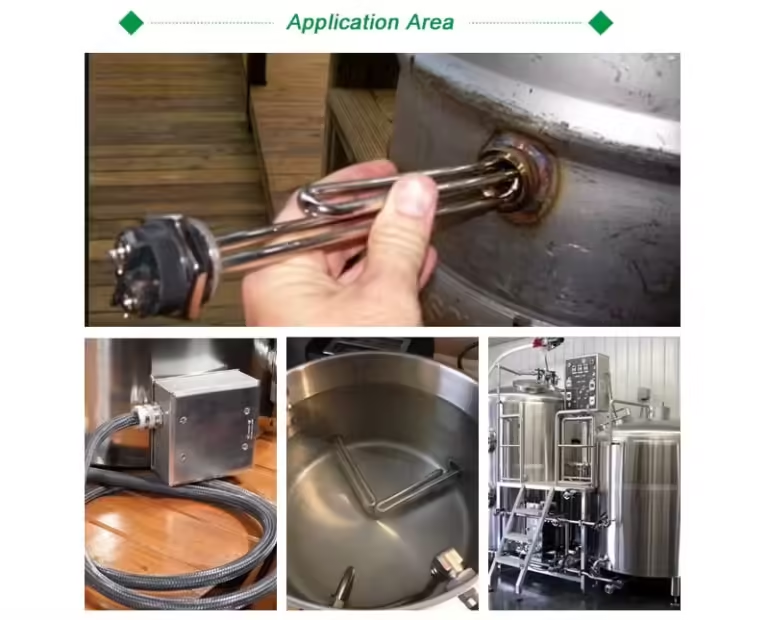

En outre, compared to traditional heating cables, self-regulating cables boast ease of installation. There’s no requirement for complex cut-to-length measurements, which translates to less time spent and fewer opportunities for error. Their versatility allows for a myriad of applications, including freeze protection of piping systems, temperature maintenance of hot water lines, and even under-floor heating.

In an era focused on optimizing resource consumption and implementing safer operational practices, self regulating heat trace cable symbolize innovative engineering. They’ve democratized access to efficient, safe, and reliable temperature management solutions, showcasing their potential for energy conservation, safety enhancement, and installation simplification.

As we journey along the path of technological innovation, it’s evident that self regulating heat trace cable provides a practical solution to a host of challenges faced by industries and households alike. With their increasing adoption across sectors, it’s clear we’re witnessing the future of temperature management solutions.

Indeed, these cables epitomize the fusion of technology and efficiency, highlighting the transformative power of self-regulation. The heat trace cable ‘thinks’ for itself, determining when to increase or decrease output, reducing the need for human intervention, facilitating operational ease, and driving us forward on our sustainable journey. A truly revolutionary concept, one that’s ignited expectations for the future.

Self regulating heat trace cable is more than just a product — they are a testament to how human ingenuity can shape technology to meet our evolving needs, casting a warm, reassuring glow that cuts through the icy shroud of uncertainty, one cable at a time.

They’re not only heating our worlds, but they’re also fueling our dreams for a more efficient, sustainable, and safe future.