An immersion cartridge heater is a versatile and efficient heating solution used across various industrial applications. These heaters are famed for their compact design, high watt densities, and capability to heat liquids and gases quickly. This article delves into immersion cartridge heaters, exploring their construction, functionality, applications, and benefits.

Construction and Design

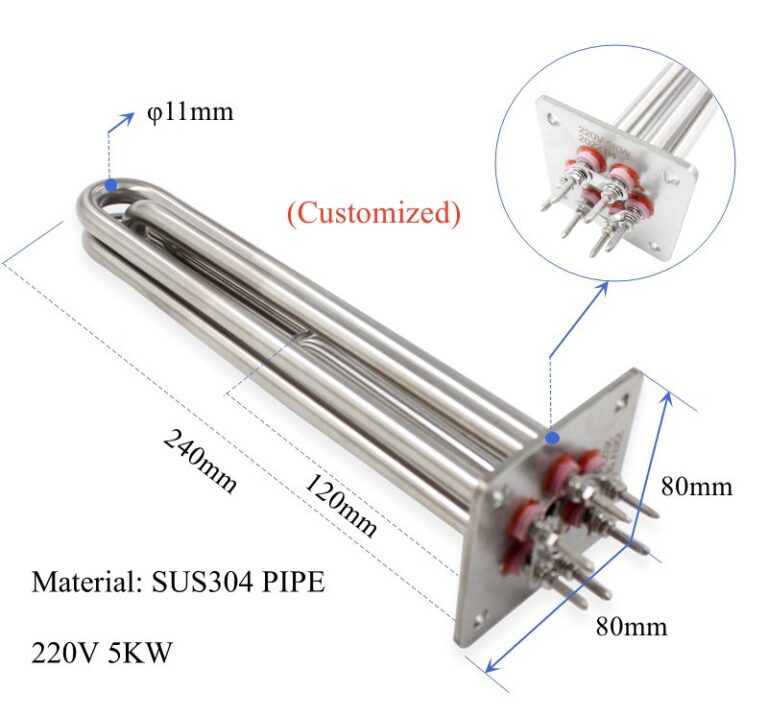

Immersion cartridge heaters consist of a cylindrical stainless steel sheath with high-grade insulation. Inside the sheath is a coil made from high-resistance Nichrome wire, whose purpose is to generate heat. The coil is compactly arranged and embedded in compacted magnesium oxide (MgO) powder, which ensures optimal thermal conductivity and electric insulation. This setup allows the heater to achieve high surface temperatures efficiently.

Below is a basic diagram showing the typical elements of an immersion cartridge heater:

| Component | Beskrivning |

|---|---|

| Stainless Steel Sheath | A durable outer layer that protects the internal components and resists corrosion. |

| Nichrome Wire Coil | A high-resistance wire that generates heat when an electric current passes through it. |

| Magnesium Oxide (MgO) | Highly compacted powder that provides insulation and enhances thermal conductivity. |

| Sealing Cap | Ensures that the internal elements remain protected and keeps contaminants out. |

How It Works

When an electric current passes through the Nichrome wire, it heats up due to electrical resistance. The heat generated by the Nichrome wire is then transferred to the sheath and subsequently to the substance being heated – whether a liquid, gas, or solid. The compact design ensures a high watt density, meaning substantial amounts of heat are delivered efficiently.

Applications

Immersion cartridge heaters find use in various industries, from chemical processing to food and beverage production. Here are some common applications:

| Ansökan | Beskrivning |

|---|---|

| Chemical Processing | Used to maintain the temperature of chemicals in tank solutions. |

| Food and Beverage | Employed in controlling the temperature of cooking oil or other liquids to ensure consistent quality. |

| Plastics Industry | Helps in the preheating process for molds and dies. |

| Pharmaceutical Manufacturing | Used to maintain sterile conditions by ensuring accurate temperature control in processing. |

| Laboratory Equipment | Ideal for precise temperature control in various lab apparatus. |

Benefits of Immersion Cartridge Heaters

High Efficiency

One of the standout benefits of immersion cartridge heaters is their high efficiency. Their compact design allows for quick and effective heating of the target medium, significantly reducing energy wastage.

Varaktighet

The stainless steel sheath gives the heater excellent durability and resistance to wear and tear, corrosion, and external damage. This makes immersion cartridge heaters a long-lasting solution for demanding environments.

Versatility

Immersion cartridge heaters are incredibly versatile. They can be used for heating fluids or gases and even for warming up solid objects. This versatility extends to their application across numerous industries, making them a go-to choice for various heating needs.

Easy Installation

The compact and cylindrical design of immersion cartridge heaters makes them easy to install. They can be inserted directly into a drilled hole or installed through a threaded fitment, making the installation process straightforward and hassle-free.

Conclusion

Sammanfattningsvis, immersion cartridge heaters are a reliable, effektiv, and versatile solution for heating needs across various industries. Their compact design and high-performance capabilities make them ideal for applications that require quick and consistent heating. Whether it’s maintaining the temperature of liquids in chemical processes or ensuring quality in food production, immersion cartridge heaters prove to be an indispensable tool.

Understanding the ins and outs of immersion cartridge heaters enables industries to leverage this technology to its fullest potential, ensuring enhanced productivity and energy efficiency.

By integrating immersion cartridge heaters into your processes, you ensure high efficiency, durability, and versatility that can form the backbone of many industrial applications. Their role in transforming how we manage heat in demanding environments cannot be overstated.