Deep fryers are an essential kitchen appliance in both commercial and home settings. These devices are instrumental in delivering crispy, golden-brown delicacies like French fries, fried chicken, and onion rings. But at the heart of every deep fryer lies a crucial component that transforms these raw ingredients into delicious creations: the heating element for fryer units.

The Role of the Heating Element

The heating element in a deep fryer is the component responsible for heating the oil to the desired cooking temperature. Without this vital part, the deep fryer would be unable to provide the intense heat required for frying food. The heating element for fryer units is designed to deliver quick and consistent heating, ensuring that the oil stays at an optimal temperature throughout the cooking process.

There are different types of heating elements used in deep fryers, each with its own set of advantages and potential drawbacks. The most common among these include electric immersion heating elements, gas burners, and induction heating elements.

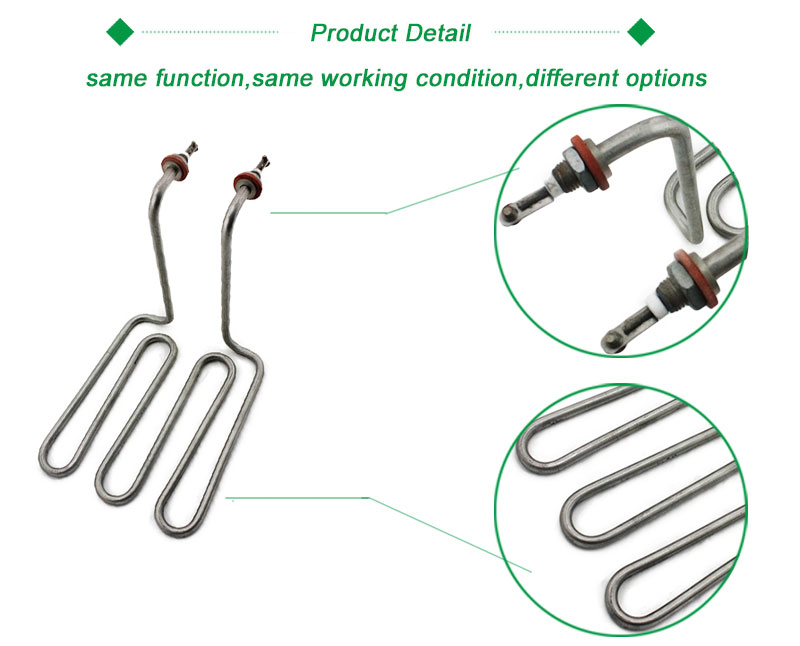

| Produkt | Tubular Heater |

| Material | stainless steel 304/321/316/310S |

| Power Tolerance | +5% -10% |

| Diameter på rör | 8MM 10MM 12MM 14MM 16MM 18MM 20MM. etc |

| Form | Round, straight, U type, W type , double W type and so on |

| Spänning | 380V 230V 220V 240V or customzied |

| Thread | M12 M14 M16 M18 |

| Ansökan | Drying,Heat Treating,Annealing,Load Banks,Curing |

Electric Immersion Heating Elements

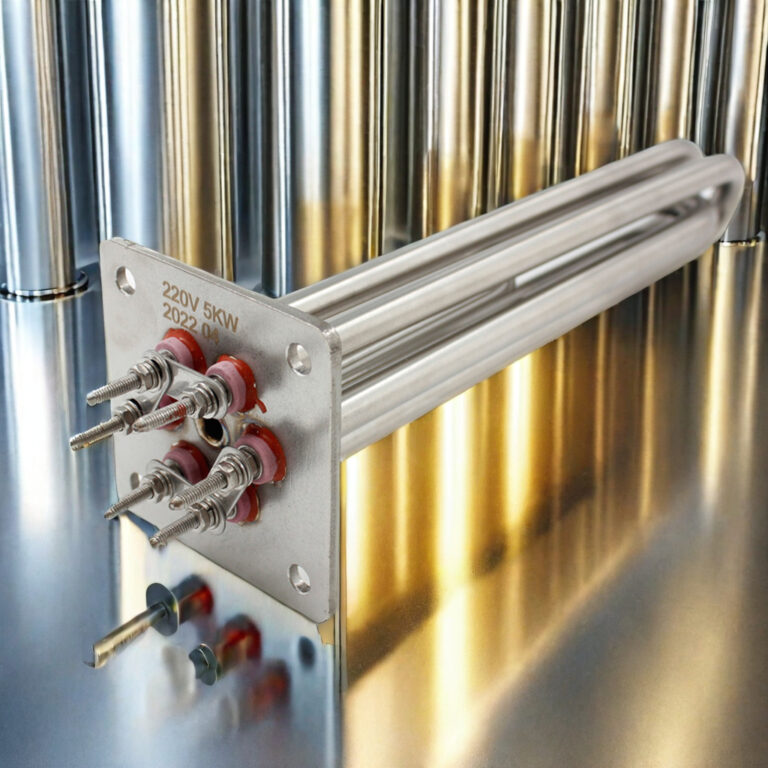

Electric immersion heating elements are the most widely used in household deep fryers. These are essentially metal coils that are submerged directly in the oil. When electricity passes through these coils, they heat up and transfer that heat to the oil. This type of heating element for fryer units is highly effective because it provides direct heat to the oil, resulting in quick heating times and efficient energy consumption.

One of the advantages of electric immersion heating elements is the ability to achieve uniform heating. The design of the coils ensures that the heat is spread evenly throughout the oil, which is crucial for cooking food evenly. Dessutom, these heating elements are relatively easy to replace or repair, making them a convenient choice for home users.

Gas Burners

Gas burners are more commonly found in commercial deep fryers, although they can also be used in high-end residential models. In this setup, a gas burner provides the heat required to raise the temperature of the oil. Gas burners can be highly effective, offering rapid heating and precise temperature control, which are important considerations in a busy kitchen environment.

The heating element for fryer units that use gas burners usually consists of a series of tubes through which the gas is burned. These burners provide intense heat and can quickly bring large quantities of oil to the desired temperature. One benefit of gas burners is that they often offer better heat recovery times, meaning the oil can return to the optimal frying temperature faster after food has been added.

Dock, gas burners come with certain drawbacks. They are typically more expensive to install and require a gas supply, which may not be practical for all settings. Dessutom, they demand more maintenance and rigorous safety precautions due to the nature of gas usage.

Induction Heating Elements

Induction heating is gaining popularity as a modern and energy-efficient alternative for deep fryers. In this method, the heating element for fryer units uses electromagnetic fields to generate heat directly within the cooking vessel. This process involves placing a compatible, ferrous metal container on an induction cooktop, where it is heated by the energy transferred from the electromagnetic fields.

Induction heating elements offer several significant advantages. They provide extremely rapid heating times and precise temperature control, which is unparalleled by other heating methods. Induction heating is also safer because there are no open flames or hot coils involved. Dessutom, these fryers tend to be more energy-efficient, reducing operational costs over time.

One limitation of induction deep fryers is the necessity for compatible cookware. The frying vessel must be made of a ferrous material, which can limit choices and increase initial setup costs.

Why the Heating Element Matters

The heating element for fryer units is crucial for achieving the best frying results. Without a reliable and efficient heating element, the oil cannot reach or maintain the proper temperature, resulting in poorly cooked food. Proper temperature control ensures that the food is cooked evenly and absorbs minimal oil, resulting in a crispy exterior and a succulent interior.

Dessutom, the type of heating element directly impacts the usability, säkerhet, and efficiency of the deep fryer. Whether you opt for an electric immersion element, a gas burner, or an induction heating element, understanding the strengths and weaknesses of each type will help you make an informed decision and get the most out of your frying experience.

In conclusion, the heating element for fryer units is the backbone of any deep fryer, whether for commercial or private use. It is the essential component that ensures delicious, evenly cooked fried foods by maintaining consistent oil temperatures. Thus, understanding the different types of heating elements available and their respective advantages can help you choose the best deep fryer for your needs and enjoy perfect fried dishes every time.