Choosing the right heater element is crucial for energy efficiency and extending the lifespan of your heating system. The heater element market is projected to grow to $16 billion by 2027, highlighting the essential role heaters play in both residential and industrial settings. Tubular and cartridge heaters, in particular, are highly effective for applications requiring precise heating.

Understanding the differences between these heater elements can help you make an informed decision. Tubular heaters provide even heat distribution, while cartridge heaters are compact and designed to heat specific areas. Comparing these options ensures you select the ideal heater element for your unique requirements.

Key Takeaways

Pick tubular heaters for spreading heat evenly over big areas. They work well in industries like food making and HVAC systems.

Use cartridge heaters for focused heat in small spaces. Their small size is great for things like plastic shaping and medical tools.

Think about saving energy when choosing heaters. New tubular heaters use 12-18% less energy, and cartridge heaters save energy by heating only needed spots.

Strong materials are important. Choose heaters made of stainless steel for long life and to handle tough conditions.

Look at both starting and long-term costs. Tubular heaters cost less at first, but cartridge heaters save money by using less energy in high-heat jobs.

Types of Heating Elements: Tubular and Cartridge Heaters

Overview of Tubular Heaters

Tubular heaters are very flexible heating tools. They spread heat evenly, which is great for keeping steady temperatures. These heaters are used in industries like food processing, chemical plants, and HVAC systems. They can be bent into different shapes to fit special equipment, making them very useful.

Manufacturers work to make tubular heaters last longer and use less energy. Many now use materials that resist rust, so they work well in tough conditions. Some advanced models even have smart features, like IoT, for better temperature control and live monitoring. This makes tubular heaters a dependable choice for both normal and high-heat jobs.

Aspect | Detalhes |

|---|---|

Advantages | Even heat, small size, custom shapes for special uses. |

Energy Efficiency Focus | Built to save energy and improve heating. |

Durability | Rust-proof materials make them last longer and work better. |

Smart Technologies | IoT helps with accurate control and live tracking. |

Overview of Cartridge Heaters

Cartridge heaters are small and powerful heating tools made for focused heating. They fit into drilled holes, so they’re easy to set up or replace. You’ll find them in plastic molding, packaging machines, and medical tools. Their small size and strong heat make them perfect for heating specific spots.

Cartridge heaters come in different sizes and materials, like stainless steel or brass, to match various needs. Their design places the heating part close to the outer layer, which helps transfer heat better and saves energy.

1/4″ | 3/8″ | 1/2″ | 5/8″ | 3/4″ | 1″ | |

|---|---|---|---|---|---|---|

Latão “A” | .98 | 1.13 | 1.25 | 1.53 | 1.72 | 2.35 |

Aço inoxidável “A” | .98 | 1.13 | 1.25 | 1.53 | 1.72 | CALL |

Key Design and Functional Differences

Tubular and cartridge heaters are different in shape, design, and how they are installed. Tubular heaters have a coiled wire inside a metal cover, while cartridge heaters keep the heating part closer to the surface. This makes cartridge heaters better for heating small areas.

How they are installed is also different. Tubular heaters are welded or attached to surfaces, but cartridge heaters slide into holes. Tubular heaters are best for spreading heat evenly, while cartridge heaters are great for focused heating.

Geometry: Cartridge heaters are simpler and heat small areas better.

Heating Element Configuration: Tubular heaters use coiled wires; cartridge heaters heat closer to the surface.

Mounting Methods: Tubular heaters are welded; cartridge heaters fit into holes.

Thermal Efficiency: Cartridge heaters save more energy because of their design.

Efficiency and Performance Comparison

Heat Distribution and Uniformity

Tubular and cartridge heaters spread heat in different ways. Tubular heaters are made to transfer heat well to surfaces. This design helps them work better and last longer. They are great for keeping steady heat over big areas.

Cartridge heaters focus on heating small, specific spots evenly. They spread heat across mold spaces, which helps make good products in plastic molding. For important uses, like medical tools, cartridge heaters may have zones you can control separately. These zones keep the temperature even and processes accurate.

Temperature Control Capabilities

Controlling temperature is important for heater performance. Tubular heaters are good for heating large areas evenly. They are not made for targeting small, exact spots.

Cartridge heaters are built for precise temperature control. They heat small areas evenly and can focus on exact spots. This makes them a top choice for industries needing steady and accurate heat.

Heater Type | Temperature Control Capability |

|---|---|

Aquecedores Tubulares | Best for heating large areas. Not for precise control. |

Cartridge Heaters | Great for exact control. Heats small areas and targets spots. |

Energy Consumption and Output

Saving energy is key for heater performance. New tubular heaters use 12-18% less energy than old ones. IoT-enabled tubular heaters are popular, especially in Germany, where use grew 22% since 2021. These heaters can reach 92% eficiência, cutting wasted energy by 35%.

Cartridge heaters also save energy with their small size and focused heat. They waste less energy by heating only needed areas. Both heater types are efficient and fit different needs, whether saving energy or heating effectively.

Evidence Type | Descrição |

|---|---|

Energy Efficiency Impact | New tubular heaters use 12-18% less energy. |

Adoption Rates | IoT tubular heaters grew 22% in Germany since 2021. |

Material Efficiency | Ceramic models reach 92% eficiência, cutting energy loss by 35%. |

Durability of Heater Elements

Material Quality and Lifespan

The material used in heaters affects how long they last. Strong materials like stainless steel and Incoloy are common in tubular and cartridge heaters. These materials resist rust and handle high heat, making them last longer. For example, stainless steel stops rust, so it works well in wet or harsh places.

How long a heater lasts depends on how it’s used and cared for. Tubular heaters spread heat evenly and often last longer in factories. Cartridge heaters are small and great for focused heating but need proper setup to last. Picking the right material for your needs helps your heater work well for a long time.

Resistance to Environmental Stress

Heaters face challenges like moisture, dust, and temperature changes. Tubular heaters are tough and work well outdoors or in factories. Cartridge heaters are small but strong if made with good materials.

Environmental Stress Screening (ESS) tests heaters in tough conditions to find problems early. This testing ensures only reliable heaters are sold. Without ESS, systems fail four times more often when first used, says the Telcordia standard. Choosing tested heaters means they’ll last in tough environments.

Maintenance and Repair Considerations

Taking care of heaters helps them last longer and work better. Following a maintenance plan prevents problems and keeps them efficient. Important tasks include:

Drain and clean the tank to remove dirt.

Check the pressure valve to avoid issues.

Replace the anode rod to stop rust.

Test the thermostat and valves for proper heat.

Clean the burner to keep it working well.

Check the vent system for blockages.

Tighten wires to avoid problems.

Check insulation to save heat.

Run a quick test to ensure it works.

Doing these steps reduces repairs and keeps your heater working well. Proper care makes sure your heater stays reliable and efficient for years.

Application Suitability of Tubular and Cartridge Heaters

Industries Benefiting from Tubular Heaters

Tubular heaters are used in many industries because they are strong and flexible. In food factories, they keep steady heat for cooking or drying. Chemical plants use them to control heat during reactions. HVAC systems rely on them to heat large areas evenly and efficiently.

These heaters work well in tough conditions, like outdoor jobs. For example, they are great in industrial ovens or furnaces with high heat and rough use. They also help in solar energy systems by heating liquids. Their ability to be shaped and sized differently makes them useful for many industries.

Applications Ideal for Cartridge Heaters

Cartridge heaters are best for jobs needing strong, focused heat. In packaging, they heat welding tools and bars efficiently. Their small size fits tight spaces, making them great for plastic molding and die-casting.

Medical tools use cartridge heaters for sterilizing and controlling heat exactly. In cars, they heat molds and dies to make parts. Their focused heat ensures good results in these special tasks.

Customization and Versatility

Both tubular and cartridge heaters can be customized to fit your needs. Tubular heaters can bend into shapes, while cartridge heaters come in various sizes and materials. This makes it easy to pick the right one for your job.

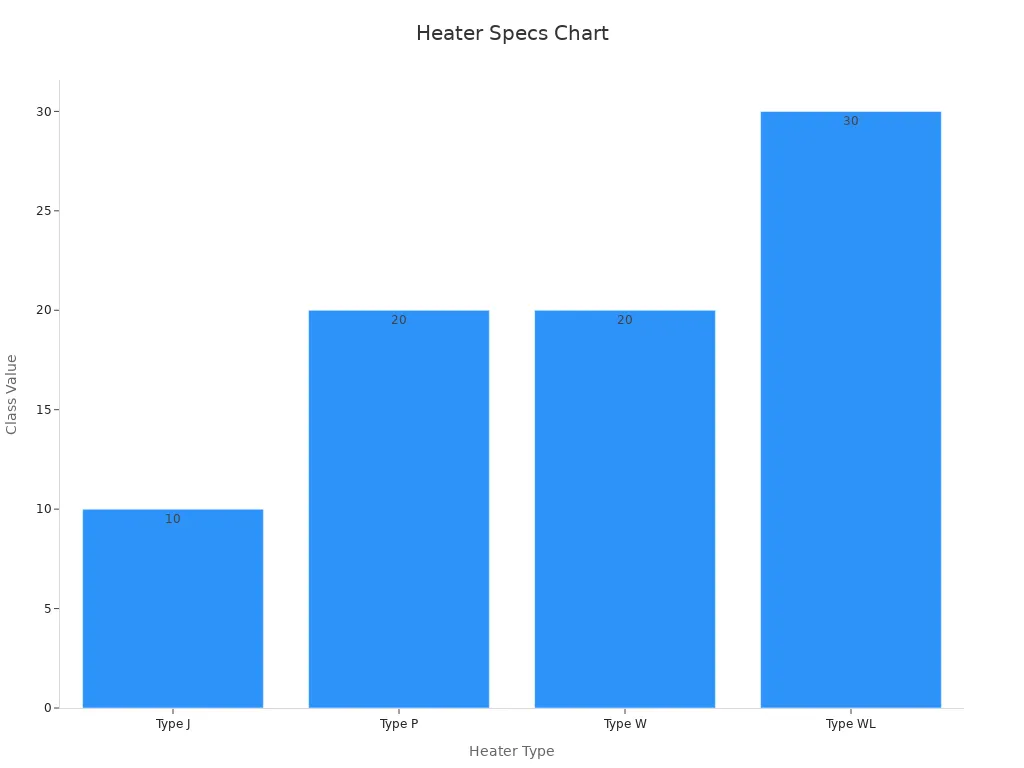

Temperature Control Options | Voltage Options | Key Features | |

|---|---|---|---|

1, 2, and 5-gallon heaters | Fixed temperature | N/A | Great for small batches and lab work |

15-gallon and 30-gallon | Fixed temperature | N/A | Good for medium industrial tasks |

55-gallon drum heaters | Fixed and adjustable temperature | 120V, 240V | Made for big industrial jobs |

Adjustable Temperature Model | Digital control (50°F to 450°F) | N/A | Offers exact heat control |

Xtreme Series | Fixed and adjustable temperature | N/A | Built tough for hard conditions |

Customizing heaters helps them work better for your needs. Whether you need exact heat control or strong durability, these heaters offer the right solutions.

Cost and Value Analysis

Initial Costs of Heater Elements

Tubular heaters usually cost less at first. This is because they have a simple design and are easy to find. Cartridge heaters, however, are often more expensive. Their small size and special build make them cost more. Reports like the Heating Coil Market Report 2025 explain that prices depend on materials, how they’re made, and market demand.

Evidence Type | Descrição |

|---|---|

Market Report | Heating Coil Market Report 2025 shares trends and market details. |

Quantitative Data | Shows market size, competitors’ shares, and tubular heater forecasts. |

Qualitative Data | Talks about factors affecting heater prices and costs. |

While upfront cost matters, think about long-term savings too. Using strong materials like stainless steel or Incoloy makes heaters last longer. This means fewer replacements and better value for your money.

Operational Costs and Energy Efficiency

Running costs are key when choosing heating elements. Electric heaters, like tubular and cartridge types, use a lot of energy in homes and factories. Studies show electric resistive heaters use 52% of heating energy in some areas. But new designs and materials now save more energy.

Electric heaters use 52% of heating energy in Toulouse.

Heating energy use may drop by 36%, saving 52 GWd.

Cooling energy use might rise by 54%, reaching 6.3 GWd.

Cartridge heaters save energy by heating only where needed. Tubular heaters with smart features keep large areas warm efficiently. Both types are energy-saving and fit different needs.

Long-Term Value and Return on Investment

Energy-efficient heaters save money over time. They lower energy bills and increase property value. For example, homes with efficient heaters attract eco-friendly buyers. Following energy rules can also earn tax credits and rebates, adding to your savings.

Performance | Best Available | ENERGY STAR | Less Efficient |

|---|---|---|---|

Uniform Energy Factor | 3.93 | 3.3 | 0.95 |

Annual Energy Use (kWh) | 826 | 984 | 3,437 |

Annual Energy Cost | $82 | $97 | $340 |

Lifetime Energy Cost | $792 | $940 | $3,440 |

$2,647 | $2,500 | ====== |

Picking the right heater saves money and meets your needs. Whether you want durability, energy savings, or precise heat, these heaters are a smart choice for long-term use.

Tubular and cartridge heaters are good for different tasks. Tubular heaters are strong, spread heat evenly, and are cheaper to install. Cartridge heaters are great for exact temperature control and save energy in high-heat jobs.

Recurso | Cartridge Heaters | Aquecedores Tubulares |

|---|---|---|

Maintenance Requirements | Easier to maintain; needs regular checks. | Needs checks for bent coils; may need replacing if broken. |

Initial Cost and Installation | Costs more upfront; harder to install. | Cheaper upfront; easier to install. |

Long-term Value and ROI | Transfers heat well, saving energy; good for hot jobs. | Best for even heating; flexible design saves money. |

Precision Control | Great for exact heat control. | Not as good for exact heat control. |

Pick the heater that fits your needs best. Think about what matters most, like accuracy, strength, or cost, to choose the right one for your job.

Perguntas frequentes

What makes tubular heaters different from cartridge heaters?

Tubular heaters spread heat evenly over big areas. This makes them great for factories. Cartridge heaters heat small, specific spots. Their small size fits tight spaces, perfect for tasks like plastic molding or medical tools.

How are coil heaters and cartridge heaters different?

Coil heaters are bendable and wrap around things for even heat. Cartridge heaters are stiff and fit into drilled holes. Coil heaters are best for flexible heating jobs. Cartridge heaters work better for focused, high-heat tasks in small spaces.

Can cartridge heaters be made for special uses?

Sim, cartridge heaters can be customized for special jobs. You can choose sizes, materials like brass or stainless steel, and power levels. This makes them great for tasks like die-casting or packaging, where exact heat is needed.

Are coil heaters good for outdoor use?

Coil heaters can be used outside if made with strong materials like stainless steel. They handle moisture and temperature changes well. But they need good insulation and care to last long and work properly outdoors.

How do you keep cartridge heaters working well?

Take care of cartridge heaters to make them last. Clean off dirt, check for damage, and tighten loose parts. Replace broken pieces quickly. These steps keep them working efficiently and avoid sudden problems during important tasks.