Silicon carbide heating elements are advanced materials utilized in high-temperature applications. These heating elements are widely used in many industrial processes due to their high thermal conductivity, resistance to thermal shock, and stability at elevated temperatures. Here’s a comprehensive exploration of the various uses and advantages of silicon carbide heating element furnace.

Introduction to Silicon Carbide Heating Elements

Silicon carbide (SiC) is a compound of silicon and carbon, known for its hardness and resistance to high temperatures. Silicon carbide heating elements are typically shaped as rods, tubes, or customized geometries to fit specific industrial needs. These elements are used in electrical resistance furnaces and kilns, where precise and consistent high temperatures are required.

| Doença | Novo | Material | Silicone |

| Tipo | Aquecedor de ar | Principais argumentos de venda | Long Service Life |

| Fonte de energia | Elétrico | Material | SIC/silicon |

| Lugar de origem | China | Forma | Straight type, U type, W type and etc. |

| SiC Content | above 99% | Diâmetro do tubo | 8mm to 65mm |

| Peso | 1KG | Nome do Produto | Silicon Carbide Rod Heating Element |

| Tensão | 110V-480V | Bulk Density | 2.8g/cm³ |

| garantia | 1 Ano | Serviço pós-venda fornecido | Video technical support, Online support, Spare parts |

| Working Temperature Range | 600℃-1625℃ | Aplicativo | Furnace heating |

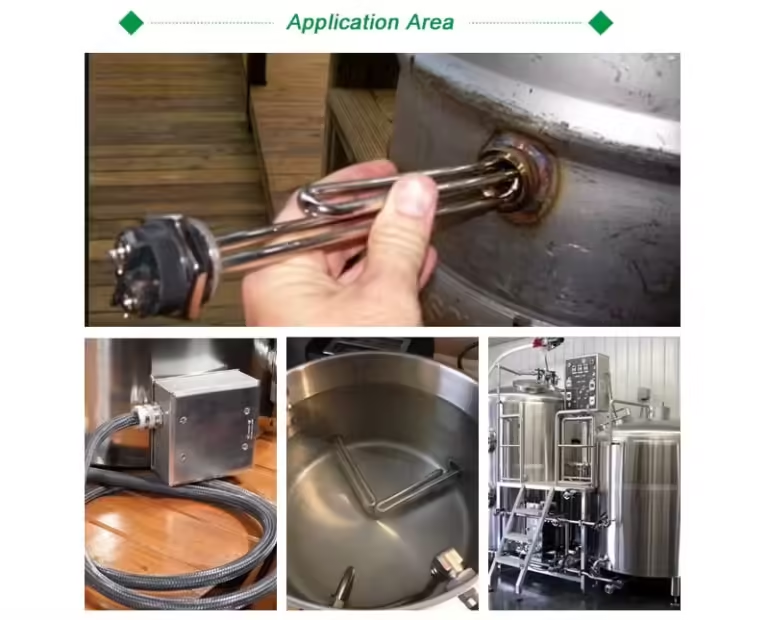

Applications of Silicon Carbide Heating Elements

1. Metallurgical Processes

Silicon carbide heating elements are indispensable in the metallurgical industry. They are used in processes such as melting, sintering, and heat treatment of metals and ceramics. In particular, silicon carbide heating element furnaces are essential in the production of high-quality steel and non-ferrous metals like aluminum and copper. These furnaces provide consistent, high temperatures necessary for alloying and refining metals.

2. Glass Manufacturing

The glass industry also benefits significantly from the use of silicon carbide heating elements. High-temperature furnaces equipped with these elements are used for melting raw materials and maintaining molten glass at specific temperatures. The rapid heating and cooling capabilities of silicon carbide heating element furnace enable efficient and cost-effective production of various glass products, including specialty glass and optical fibers.

3. Semiconductor Industry

In the semiconductor industry, silicon carbide heating elements are used in diffusion and oxidation furnaces. These furnaces require precise temperature control to create high-purity silicon wafers, essential for manufacturing semiconductors. The thermal stability and long lifespan of silicon carbide elements make them a preferred choice for these critical processes.

4. Ceramic and Refractory Manufacturing

Silicon carbide heating elements play a crucial role in the ceramic industry. They are used in kilns for firing and sintering ceramic materials. The high temperatures and uniform heating provided by silicon carbide elements ensure the strength and quality of the final ceramic products. Refractory materials, which must withstand extreme conditions, are also processed in silicon carbide heating element furnace.

5. Chemical Processing

In chemical research and manufacturing, controlled high-temperature environments are often necessary. Silicon carbide heating elements are used in reactors and furnaces to provide the required heat for chemical reactions, cracking processes, and material synthesis. Their resistance to corrosive atmospheres and chemical stability makes them ideal for these applications.

Advantages of Silicon Carbide Heating Elements

1. High-Temperature Stability

Silicon carbide heating elements can operate at temperatures up to 1600°C (2912°F). This high-temperature capability makes them suitable for many demanding industrial processes.

2. Rapid Heating and Cooling

The excellent thermal conductivity of silicon carbide allows for rapid heating and cooling cycles. This feature is beneficial in processes requiring quick temperature adjustments, reducing downtime and improving production efficiency.

3. Longevity and Durability

Silicon carbide heating elements have a long operational life, even in harsh environments. Their resistance to oxidation and thermal shock ensures that they maintain their efficiency over extended periods, thereby reducing maintenance costs.

4. Energy Efficiency

These heating elements are energy-efficient, providing consistent and uniform heating. Their ability to transfer heat effectively minimizes energy consumption and enhances overall process efficiency.

5. Versatility

Silicon carbide heating elements can be customized to fit various furnace designs and applications. This versatility allows them to be used across multiple industries with specific heating requirements.

Conclusion

Silicon carbide heating elements are a crucial component in many high-temperature industrial processes. Their unique properties, such as high-temperature stability, rapid heating and cooling, durabilidade, energy efficiency, and versatility, make them indispensable in industries like metallurgy, glass manufacturing, semiconductors, cerâmica, and chemical processing.

By understanding the applications and advantages of silicon carbide heating element furnace, industries can make informed decisions about integrating these advanced materials into their production processes, leading to improved efficiency, reduced costs, and enhanced product quality.