When it comes to heating liquids, whether it’s water, oil, or other substances, immersion heating elements play a crucial role. These versatile devices are designed to heat liquids directly by immersing them into the substance, providing efficient and reliable heat transfer. In this article, we will explore the workings of immersion heating elements, their applications, and the benefits they offer.

How Immersion Heating Elements Work

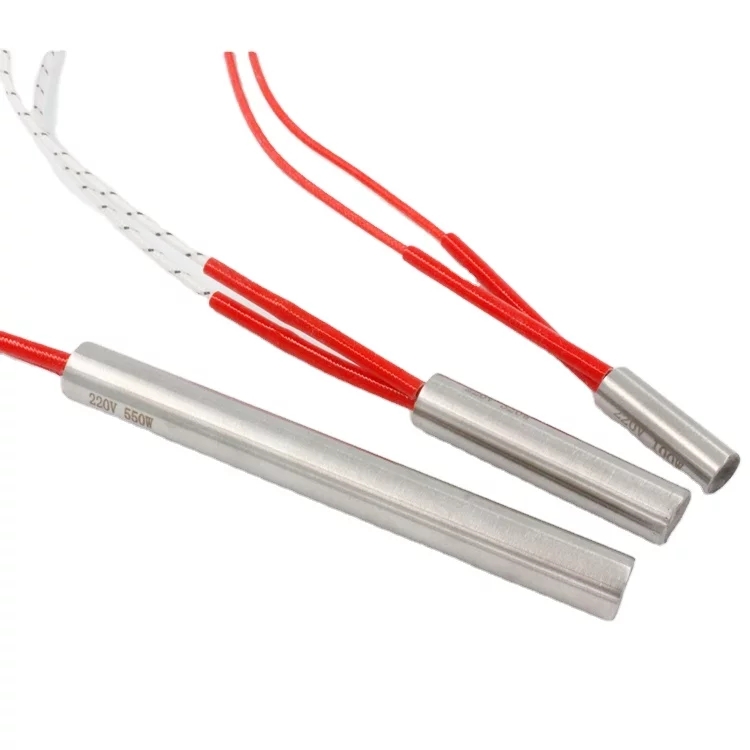

An immersion heating element consists of a heating coil encased in a sheath made of a corrosion-resistant material such as stainless steel or titanium. The coil is typically made of a high-resistance alloy such as nichrome or kanthal, which generates heat when an electric current passes through it. The sheath protects the coil from direct contact with the liquid, ensuring safety and preventing contamination.

Immersion heating elements are designed to be inserted into a liquid-filled tank or container, where they transfer heat directly to the liquid. The element is connected to a power source, and when the current flows through the coil, it heats up, raising the temperature of the surrounding liquid. The heat transfer is efficient and uniform, ensuring that the entire liquid is heated evenly.

Applications of Immersion Heating Elements

Immersion heating elements find wide-ranging applications in various industries and settings:

1. Water Heating

One of the most common uses of immersion heating elements is in water heaters. Whether it’s for residential, commercial, or industrial purposes, immersion heaters are used to heat water efficiently and quickly. They are found in water boilers, hot water tanks, and even in solar water heating systems.

2. Oil Heating

Immersion heating elements are also widely used for heating oil in industrial processes. They are commonly found in oil storage tanks, oil refineries, and oil extraction facilities. The precise temperature control offered by immersion heaters ensures optimal oil viscosity for various applications.

3. Chemical Processing

In the chemical industry, immersion heating elements are used for precise temperature control in various processes. They are utilized in reactors, distillation columns, and other equipment that require heating of chemical substances. The ability to heat liquids quickly and uniformly makes immersion heaters an ideal choice for these applications.

4. Food and Beverage Industry

Immersion heating elements are commonly used in the food and beverage industry for processes such as pasteurization, esterilização, and cooking. They are found in equipment like industrial ovens, steamers, and kettles, ensuring efficient and hygienic heating of food and beverage products.

Benefits of Immersion Heating Elements

There are several advantages to using immersion heating elements:

1. Efficient Heat Transfer

Immersion heaters offer efficient heat transfer due to their direct contact with the liquid. This ensures rapid heating and reduces energy consumption compared to other heating methods.

2. Precise Temperature Control

Immersion heating elements provide precise temperature control, allowing for accurate heating of liquids to the desired temperature. This is crucial in industries where temperature control is critical for process efficiency and product quality.

3. Versatility

Immersion heaters are versatile and can be customized to suit different applications. They come in various shapes and sizes, allowing for easy installation in different types of tanks and containers.

4. Durability

The sheath material used in immersion heating elements is corrosion-resistant, ensuring long-lasting performance even in harsh environments. This makes them suitable for a wide range of industries and applications.

5. Easy Maintenance

Immersion heaters are relatively easy to maintain. They can be accessed and replaced without draining the entire tank or system, minimizing downtime and maintenance costs.

Para concluir, immersion heating elements are essential devices for heating liquids in various industries and applications. Their efficient heat transfer, precise temperature control, and versatility make them a reliable choice for water heating, oil heating, chemical processing, and the food and beverage industry. With their durability and easy maintenance, immersion heaters offer a cost-effective solution for heating liquids effectively and efficiently.