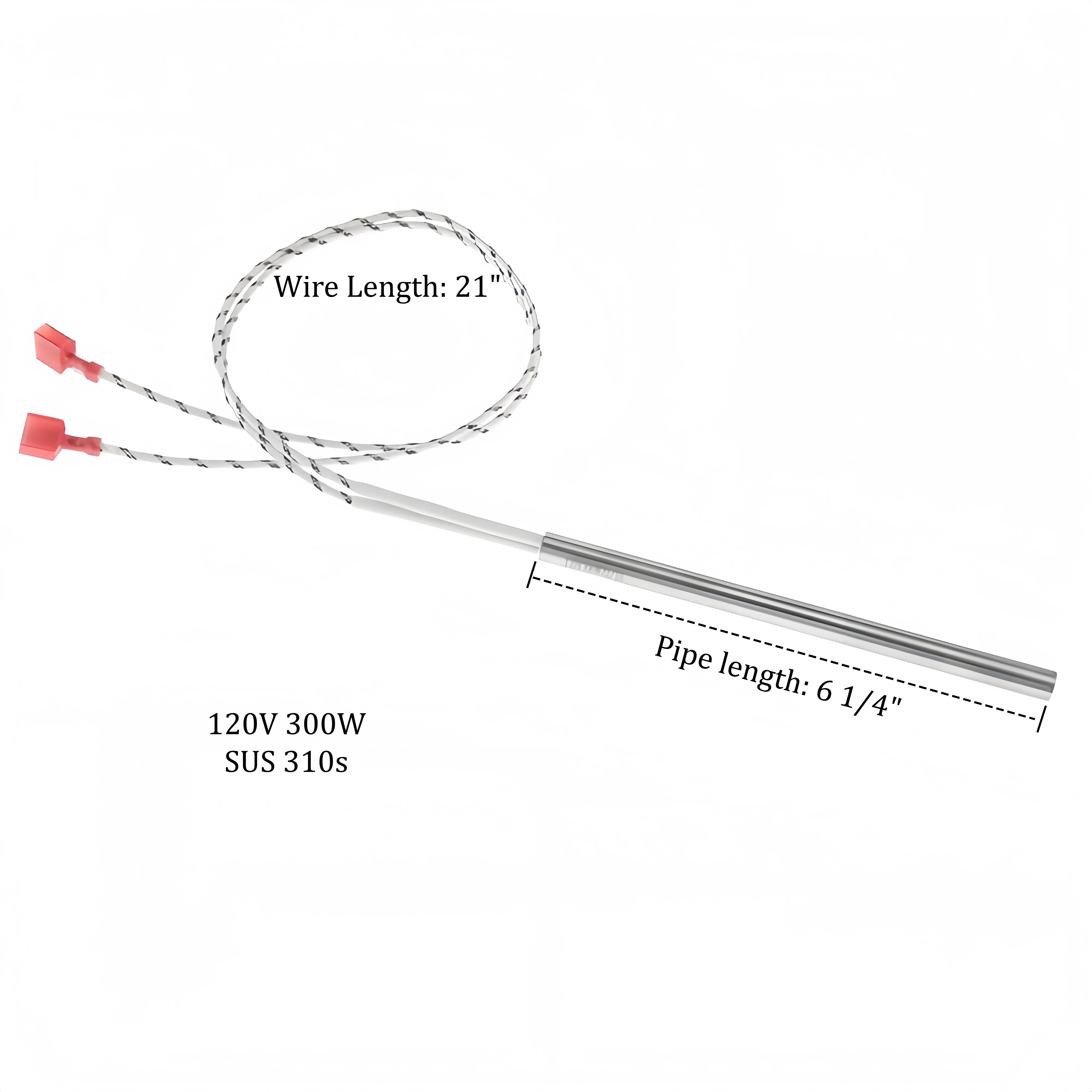

80604 Stove Igniter Replacement 120V 300W for US Stove Vogelzang Ashley King Pellet Stove Igniter 80604 Hot Rod Heating Element

80604 Stove Igniter Replacement 120V 300W for US Stove Vogelzang Ashley King Pellet Stove Igniter 80604 Hot Rod Heating Element

Description

80604 Stove Igniter Replacement 120V 300W for US Stove Vogelzang Ashley King Pellet Stove Igniter 80604 Hot Rod Heating Element

Product Description

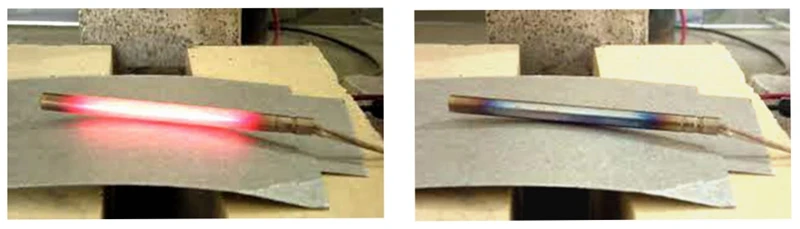

1. Efficient ignition, rapid heating

The high-quality heating elements ensure rapid heating with a 300W power output. The ignition response is swift, compared to ordinary low-power igniters, which can shorten the start-up time of the stove by 20%-30% without the need for long waiting periods. It provides timely heating in winter. At the same time, the surface temperature of the heating rod is stable, continuously providing sufficient initial heat for the pellet fuel combustion, reducing the probability of ignition failure.

2. Durable materials, long-term use

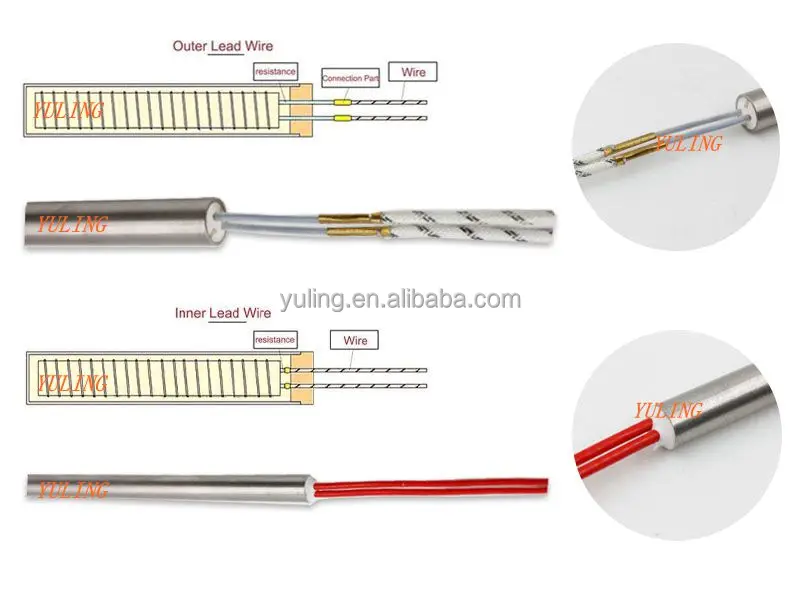

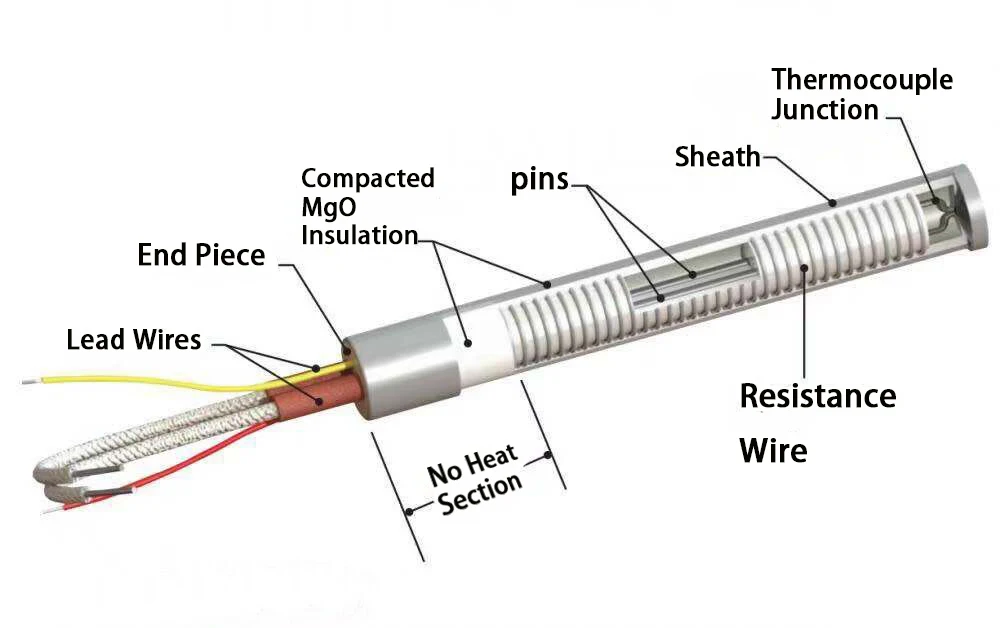

The core components of the igniter are made of high-temperature-resistant alloy materials, capable of withstanding the high-temperature environment inside the pellet stove (with a maximum tolerance temperature of over 800°C). This effectively resists high-temperature oxidation and corrosion, extending the service life. The outer insulation protective cover has undergone strict temperature tests to avoid the risk of electric leakage, making it safer to use.

3. Precise fit, easy installation

It is produced strictly in accordance with the original 80604 igniter’s size and interface standards, including details such as terminal connectors and installation holes, which are fully matched. No modification of the stove structure or additional drilling is required. Users only need to replace it according to the original wiring method, and even beginners can complete the installation easily, saving maintenance time and labor costs.

4. Stable operation, energy saving and consumption reduction

The igniter heats evenly, ensuring the full combustion of pellet fuel, reducing the waste of unburned fuel, improving the stove’s thermal efficiency, and indirectly reducing fuel consumption costs. At the same time, the stable ignition performance avoids frequent restarts, which cause wear and tear on the internal components of the stove, prolonging the overall equipment service life.

The high-quality heating elements ensure rapid heating with a 300W power output. The ignition response is swift, compared to ordinary low-power igniters, which can shorten the start-up time of the stove by 20%-30% without the need for long waiting periods. It provides timely heating in winter. At the same time, the surface temperature of the heating rod is stable, continuously providing sufficient initial heat for the pellet fuel combustion, reducing the probability of ignition failure.

2. Durable materials, long-term use

The core components of the igniter are made of high-temperature-resistant alloy materials, capable of withstanding the high-temperature environment inside the pellet stove (with a maximum tolerance temperature of over 800°C). This effectively resists high-temperature oxidation and corrosion, extending the service life. The outer insulation protective cover has undergone strict temperature tests to avoid the risk of electric leakage, making it safer to use.

3. Precise fit, easy installation

It is produced strictly in accordance with the original 80604 igniter’s size and interface standards, including details such as terminal connectors and installation holes, which are fully matched. No modification of the stove structure or additional drilling is required. Users only need to replace it according to the original wiring method, and even beginners can complete the installation easily, saving maintenance time and labor costs.

4. Stable operation, energy saving and consumption reduction

The igniter heats evenly, ensuring the full combustion of pellet fuel, reducing the waste of unburned fuel, improving the stove’s thermal efficiency, and indirectly reducing fuel consumption costs. At the same time, the stable ignition performance avoids frequent restarts, which cause wear and tear on the internal components of the stove, prolonging the overall equipment service life.

Wattage Tolerance | +5%, -10% |

Resistance tolerance | +10%, -5% |

Voltages available | 380V,240V, 220V,120V,110V,36V,24V or 12V |

Max operating temp | 870ºC(1600F) |

Length tolerance | ± 2% or 3.2mm (1/8”), whichever is greater. |

Camber tolerance | 1.7mm per meter (0.020” per foot). |

Diameter tolerance | Diameter at each end may vary +0.05mm -0.1mm (+.002″ -.004″) |

Standard Unheated Area | 5-10mm; |

Internal thermocouple | type J or K; |

Thermocouple Location | Disc End, Sheath, Center of Heater; |

Insulation resistance (cold) | ≥ 500 MΩ; |

Maximum leakage current (cold) | ≤ 0.5 mA; |

Diameter | from 3.0mm to 30mm; |

Function:

1. Operating conditions: ambient temperature-20℃ ~ + 60℃, relative temperature <80%;2. Electrical strength: cold withstand voltage AC work 1500V 50Hz lasts for 1 min without breakdown phenomenon;3. Thermal insulation performance: AC 1000V 50Hz lasts for 1 min without breakdown phenomenon;4. Leakage current <0.5MA; Insulation resistance> 30MΩ;

Application

* Injection moulding-Internal heating of nozzies* Hot runner systems-Heating of manifolds* Packaging industry-Heating of cutting bars* Packaging industry-Heating of hot stamps* Laboratories-Heating of analytical equipment* Medical:Dialysis,sterilization,Blood Analyzer,Nebulizer,Blood/Fluid Warmer,Temperature Therapy* Telecommunications:Deicing,Enclosure Heater* Transportation:Oil/Block Heater,Aiecraft Coffee Pot Heaters,* Food Service:Steamers,Dish Washers,* Industrial:Packaging Equipment,Hole Punches,Hot Stamp.

Customer Evaluation

Packing & Delivery

Plastic bag & Carton box

Certificate

Company Profile

FAQ

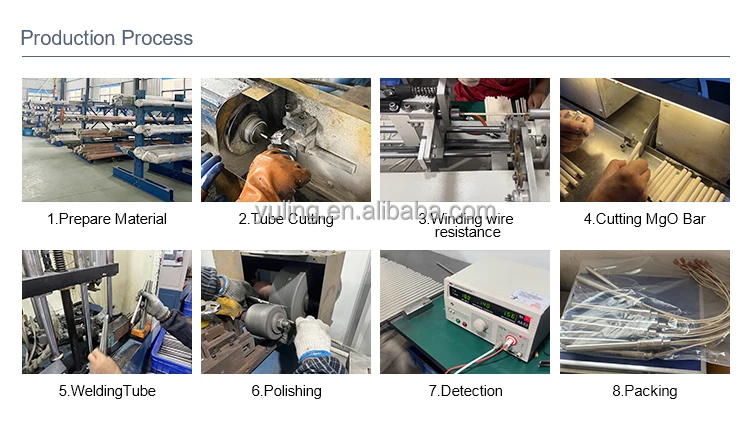

1. who are we?We are based in Jiangsu, China, start from 2010,sell to Oceania(50.00%),North America(30.00%),South America(10.00%),Southern Europe(10.00%). There are total about 11-50 people in our office.2. how can we guarantee quality?Always a pre-production sample before mass production;Always final Inspection before shipment;3.what can you buy from us?Cartridge Heater/Cast-In Heater/Circulation Heater/Enginee Block Heater/Open Coil Heater, Finned Heater/Strip Heater/Heating Element4. why should you buy from us not from other suppliers?1.More than 40 years experence

2.UL CE RoHS CQC ISO9001:2008

3.The R&D team

4.Provide test report

5.Support product design5. what services can we provide?Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDU,Express Delivery;Accepted Payment Currency:USD,EUR,CNY;Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;Language Spoken:English,Chinese,French

2.UL CE RoHS CQC ISO9001:2008

3.The R&D team

4.Provide test report

5.Support product design5. what services can we provide?Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDU,Express Delivery;Accepted Payment Currency:USD,EUR,CNY;Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;Language Spoken:English,Chinese,French

You must be logged in to post a review.

Reviews

There are no reviews yet.