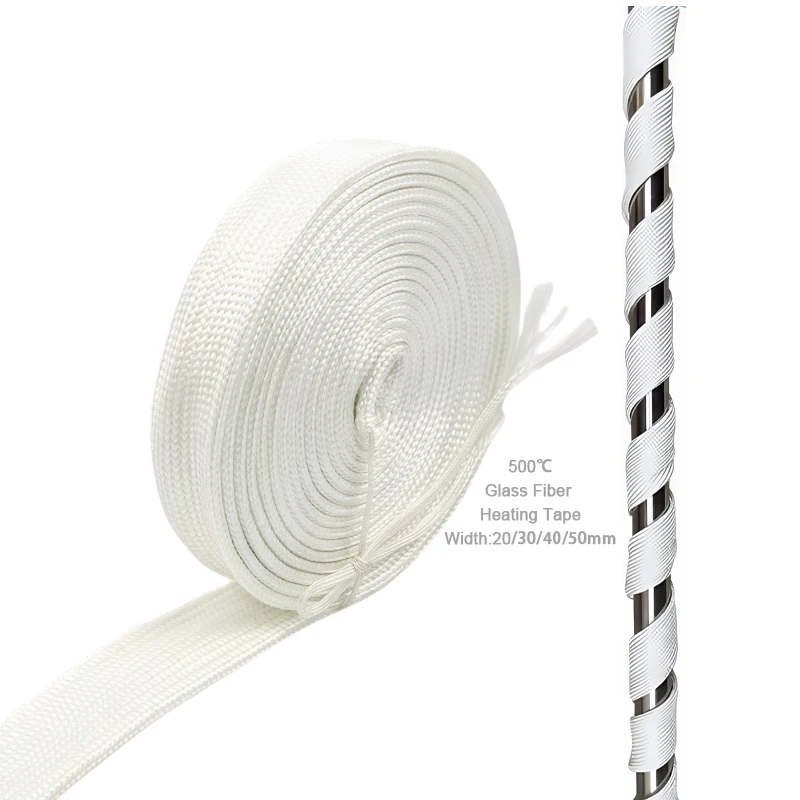

Electric Power Cable Heat Trace Cable Heating Tape 500C High Temperature Fiberglass Braid Heating Belt for Pipeline

Electric Power Cable Heat Trace Cable Heating Tape 500C High Temperature Fiberglass Braid Heating Belt for Pipeline

Opis

Electric Power Cable Heat Trace Cable Heating Tape 500C High Temperature Fiberglass Braid Heating Belt for Pipeline

Opis produktu

Fibergalss Electric Heating Cable

Fiberglass electric heating cable is suitable for heating and heat preservation of tanks, rurki, tanks and other containers ofvarious industrial equipments. It is mainly composed of electrothermal materials and insulating materials. The electrothermalmaterials are nickel-chromium alloy belts, which have fast heat generation and high thermal efficiency.

Long service life, the insulation material is multi-layer alkali-free glass fiber, with good temperature resistance and reliableinsulation performance. The utility model has the advantages of soft structure, can be directly wound on the surface of the heatedpart when used, and has uniform temperature, simple installation, convenient use, safety and reliability.

Specyfikacja

Structural Performance(1) It is mainly composed of nickel-chromium alloy wires and insulating material, and has fast heating speed, high heat efficiency and long service life.(2) Alkali-free glass fiber core rack is wound with electric heating wires, fiberglass is used as main insulation, the heatresistance performance is excellent, and the insulation performance is reliable.(3) It has great flexibility, and can be directly wound on a to-be-heated device, with good contact and uniform heating.Note: fiberglass heating cable do not have the functions of waterproof and moistureproof .

Produkt | Napięcie(V) | Moc(W) | Width(mm) | Rezystancja izolacji | Maximum Temperature |

RDG–1 | 220 | 100 | 10-30 | >2MΩ | ≤500℃ |

RDG–2 | 220 | 200 | 10-30 | ||

RDG–3 | 220 | 300 | 10-30 | ||

RDG–4 | 220 | 400 | 10-30 | ||

RDG–5 | 220 | 500 | 10-30 | ||

RDG–6 | 220 | 600 | 10-30 | ||

RDG–7 | 220 | 700 | 10-30 | ||

RDG–8 | 220 | 800 | 10-30 | ||

RDG–9 | 220 | 900 | 10-30 | ||

RDG–10 | 220 | 1000 | 10-30 |

Instrukcje Instalacji

Step 1: Pipe Surface PreparationPrepare surface to be heated: Wipe the surface making sure there is no foreign material, like liquid, on the surface. Foreignmaterial inhibits heat transfer and liquid can damage select models of heating tape (i.e. HighTemperature Heating Tapes).Make a visual inspection of heating tape: We recommend that you replace the heating tape if it becomes torn or damaged. Damaged heating tape is a safety hazard and will not operate correctly.Step 2: Heating Tape Installation (wrap)Heating tape can be installed on nearly any surface due to its flexibility. Spiral wrap the heating tape onto the surface to beheated so that the length of one entire side of the heating tape is in full contact with the surface .The distance between spiral wraps is dependent on the uniformity requirements and the amount of available heating tape. A minimum distance of 1/8” is required between spiral wraps to avoid damage to the heating tape.Attach the heating tape to the surface by either using built-in tie straps, high-temperature adhesive tape or mechanical clamping devices that will not cause damage to the heating tape.Ensure the heating tape is not kinked, twisted, or hanging free from the surface.Do not overlap heating tape on itself.This can cause damage to the heating tape due to overheating.Step 3: Connecting Your Heating Tape to a Temperature Controlling DeviceYour heating tape must be connected to an external temperature control device. Ensure your temperature controller is protected by a properly sized circuit breaker or fuse. Use of a ground fault circuit interrupter is highly recommended and may be required for your installation.For proper temperature control, secure a thermocouple, RTD, or other sensing device with one strip of adhesive tape so that it is in close proximity to the heater to prevent overheating.

Uszczelka & Dostawa

Często zadawane pytania

1. kim jesteśmy?Nasza siedziba znajduje się w Jiangsu, Chiny, zacznij od 2010 roku, sprzedaj do Oceanii(50.00%),Ameryka północna(30.00%),Ameryka Południowa(10.00%),Południowa Europa(10.00%). Jest ich łącznie około 11-50 ludzie w naszym biurze.2. jak możemy zagwarantować jakość?Zawsze próbka przedprodukcyjna przed produkcją masową;Zawsze ostateczna kontrola przed wysyłką;3.co możesz u nas kupić?Nagrzewnica kasetowa/Nagrzewnica odlewana/Nagrzewnica obiegowa/Nagrzewnica bloku silnika/Nagrzewnica z otwartą wężownicą, Grzejnik żebrowany / grzejnik taśmowy / element grzejny 4. dlaczego warto kupować u nas, a nie u innych dostawców?1.Więcej niż 40 lata doświadczenia

2.UL CE RoHS CQC ISO9001:2008

3.R&Zespół D

4.Dostarcz raport z testu

5.Wsparcie projektowania produktu 5. Jakie usługi możemy dostarczyć?Zaakceptowane Warunki Dostawy: KIESZONKA NA ZEGAREK,CFR,CIF,EXW,DDU,Przesyłka ekspresowa;Akceptowana waluta płatności:USD,EUR,CNY;Akceptowany rodzaj płatności: T/T,Akredytywa,D/P D/A,MoneyGram,Karta kredytowa,PayPal,Western Union,Gotówka,Escrow;Język używany:język angielski,chiński,Francuski

2.UL CE RoHS CQC ISO9001:2008

3.R&Zespół D

4.Dostarcz raport z testu

5.Wsparcie projektowania produktu 5. Jakie usługi możemy dostarczyć?Zaakceptowane Warunki Dostawy: KIESZONKA NA ZEGAREK,CFR,CIF,EXW,DDU,Przesyłka ekspresowa;Akceptowana waluta płatności:USD,EUR,CNY;Akceptowany rodzaj płatności: T/T,Akredytywa,D/P D/A,MoneyGram,Karta kredytowa,PayPal,Western Union,Gotówka,Escrow;Język używany:język angielski,chiński,Francuski

Musisz być zalogowany aby opublikować recenzję.

Opinie

Nie ma jeszcze żadnych recenzji.