오븐 발열체

오븐 발열체: Kitchen delicious behind the scenes hero

In every food-loving home, ovens are indispensable kitchen appliances. They are magic boxes for making all kinds of delicious dishes, from golden crispy roasted chicken wings, to fragrant cakes, to spongy, delicious breads that are mouth-watering. 하지만, behind these delicacies, there is a key role in silent dedication – the oven heating element, which is like a behind-the-scenes hero, with its own heat, to bring us endless delicious enjoyment.

오븐 발열체

The working principle of the oven heating element is revealed

The operating principle of the oven heating element is based on Joule’s law, which states that when an electric current passes through a conductor, heat is generated due to the resistance of the conductor. Simply put, when the current passes through the resistance wire in the heating element, the resistance wire heats up, converting electrical energy into heat. This heat energy is transferred through the wall of the heating element to the inside of the oven, which in turn heats the air and food inside the oven.

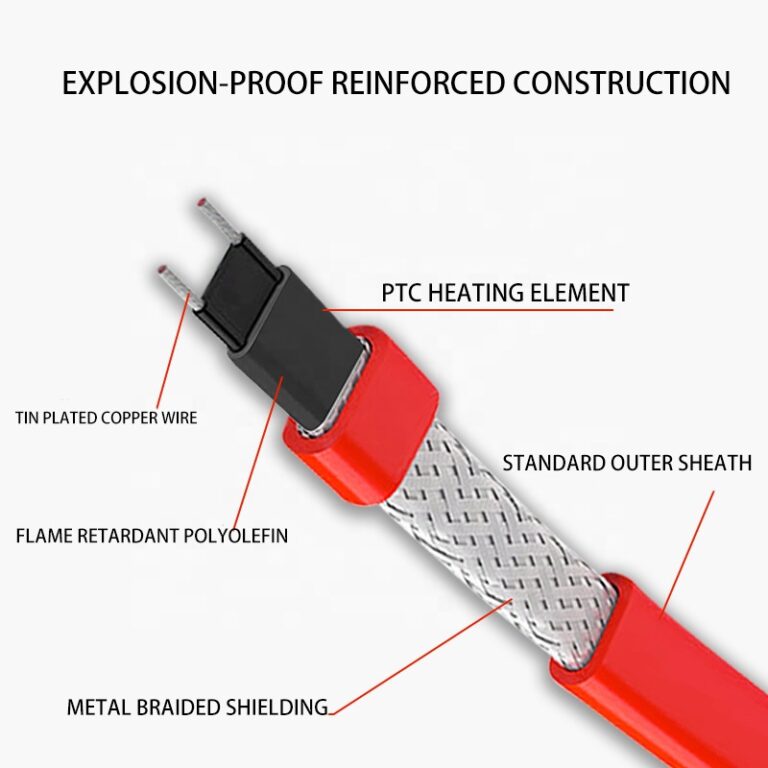

The heating element is usually composed of metal element, 저항선, insulation material and sealing material. Metal element as a shell, play a role of protection and support; The resistance wire is the core component that generates heat and is usually made of high resistivity alloys, such as nickel-chromium alloy; The insulation material is filled between the resistance wire and the metal element to ensure that the current does not leak, while also helping to improve the efficiency of heat transfer; The sealing material is used to seal both ends of the heating element to prevent dust, moisture, 등., from entering the interior, affecting the performance and life of the heating element.

During the working process, when the oven is connected to the power supply, the current passes through the resistance wire of the heating element, and the resistance wire rapidly heats up. Due to the good thermal conductivity of the metal element, heat can be quickly transferred from the resistance wire to the surface of the metal element, which in turn heats the air in the oven. The hot air circulates in the oven and transfers heat to the food through convection and radiation, so that the food is evenly heated to achieve the purpose of baking.

This working principle allows the heating element to quickly and efficiently convert electrical energy into heat, providing a stable heat source for the oven and ensuring that food can be cooked just right in a short time. Whether it is the uniform heat required for baking bread, or the crisp on the outside and tender on the inside when baking chicken wings, the heating element can meet various baking needs with its unique working principle, bringing us a delicious baking and barbecue experience.

오븐 발열체

Different types, different abilities

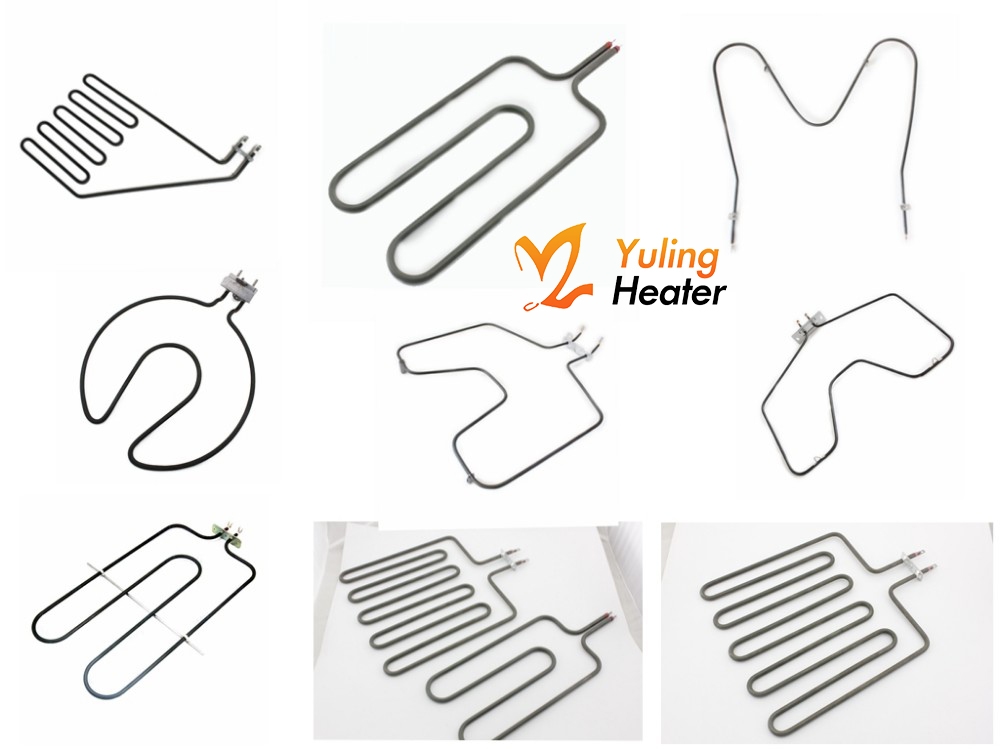

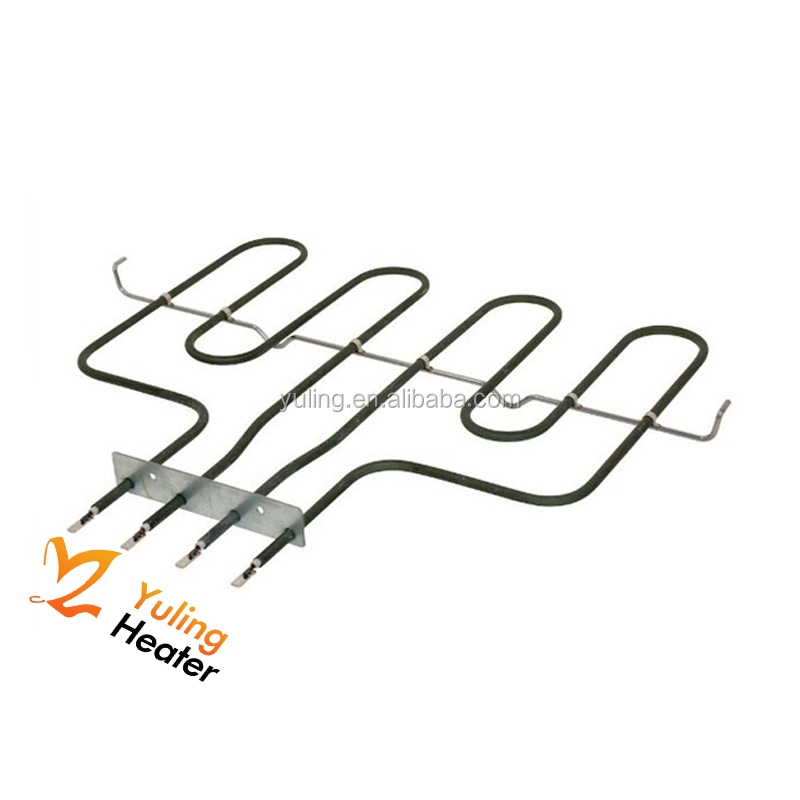

In the world of ovens, the types of heating elements are rich and diverse, each with its own unique characteristics and advantages, and they play an important role as right-hand men in the kitchen, bringing us different cooking experiences.

오븐 발열체

Stainless steel oven heating element

Stainless steel heating element is one of the most widely used heating element types in the market. Its surface is treated by a special bluing technology, forming a layer of blue passivation film, which is like putting on a layer of strong armor for the heating element, with strong corrosion resistance. In daily use, whether it is in the face of high temperature and high humidity environment in the oven, or the erosion of food residue, the stainless steel heating element can maintain good performance with this passivation film, which is not easy to rust and damage, and greatly extends the service life.

In addition to excellent corrosion resistance, stainless steel heating elements also have the advantages of high thermal efficiency and fast heating. When the current generates heat through the resistance wire, the stainless steel element wall can quickly transfer the heat out, so that the temperature in the oven rises rapidly, so that the food can be heated evenly in a short time, to achieve the ideal baking effect. 게다가, due to its fast heating speed, it can effectively shorten the cooking time and save energy, which is very in line with the needs of modern fast-paced life.

Whether it is daily household baking or frequent use in commercial baking, stainless steel heating elements can work stably and reliably, bringing users an efficient and convenient cooking experience. Its stability and durability make it the first choice of many consumers and businesses, and it is a well-deserved main force in the oven.

오븐 발열체

Quartz element

Quartz element heating elements once occupied a place in the field of ovens. Its outer surface is composed of quartz element, the diameter of the element is relatively large, and there is an air barrier between the internal heating wire and the outer surface. This structure makes the power of a single quartz element larger than that of a single stainless steel heating element, so when baking food, it can quickly generate a lot of heat, and the fast baking speed is a significant advantage. When baking some foods with high time requirements, such as pancakes, small cookies, 등., quartz elements can quickly bake the food and maintain the taste and flavor of the food.

하지만, quartz elements also have obvious disadvantages. Because it is a glass material, the texture is relatively brittle, in the process of transportation and use, once subjected to collision or vibration, it is prone to damage. This will not only affect the normal use of the oven, but also may lead to safety risks. 게다가, the service life of the quartz element is relatively short, and it needs to be replaced frequently, which increases the cost of use and maintenance. With the development of technology and the improvement of consumer requirements for product quality, the use of quartz elements in oven ovens has gradually decreased and gradually been replaced by other higher-quality heating element types.

Light wave element

The light wave element is a heating element using a unique broadcast technology that emits visible and far-infrared heat lines to bake food in a new way of conduction heating. This special heating method makes the light wave element have many advantages that other heating elements cannot match.

No preheating is a prominent feature of light wave element. When using an ordinary oven, we often need to preheat 5-10 minutes in advance and wait for the temperature in the oven to reach the set value before we can start baking food, which not only wastes time, but also consumes additional energy. The light wave element oven does not need to be preheated, as long as the power is turned on, it can start working immediately, greatly improving the baking efficiency, so that we can enjoy delicious food more quickly.

The color of the light Wave Grill is also excellent. When baking roasted whole chicken, roasted chicken wings and other foods, the light wave element can make the surface of the food evenly heated, and quickly form a layer of attractive golden skin, which is not only beautiful in color, but also crispy in taste, which makes people’s appetite increase.

게다가, the light wave element also has the function of light wave sterilization. When baking food, the light wave it emits can sterilize the inside of the oven, effectively remove bacteria and odor, keep the oven clean and sanitary, and provide protection for our health. Due to its advanced technology and excellent performance, the light wave element is mostly used in high-end models, which brings a more convenient, efficient and healthy baking method for users who pursue high-quality cooking experience.

오븐 발열체:The deep relationship between material and quality

오븐 발열체:The mystery of metal

In the world of oven heating elements, metal materials play a pivotal role, of which 304 stainless steel and 316L stainless steel are the two most common materials, and there are some significant differences in performance.

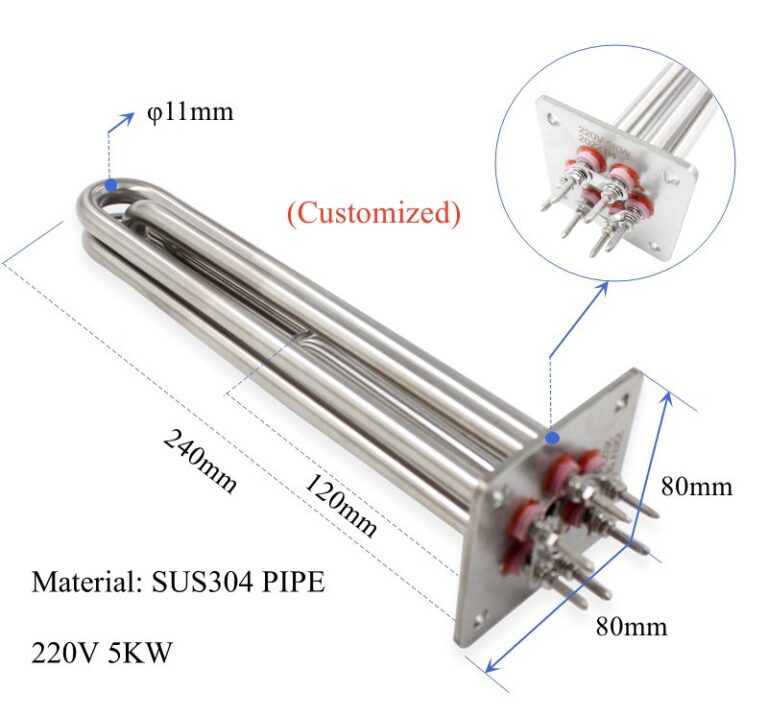

304 stainless steel is a widely used austenitic stainless steel, with good corrosion resistance, heat resistance and low temperature strength and mechanical properties. In the ordinary baking environment, it can work stably and provide a reliable heat source for the oven. Its thermal conductivity is moderate, and it can effectively transfer the heat generated by the resistance wire to the inside of the oven, so that the food is evenly heated. 게다가, 304 stainless steel has good thermal processing properties such as stamping and bending, and is easy to process into various shapes of heating elements to meet the design needs of different ovens.

316L stainless steel is based on 316 stainless steel to reduce the carbon content, while containing 2-3% molybdenum, which makes its corrosion resistance and high temperature resistance to a higher level. Especially in the face of harsh environments such as high humidity and high salt, 316L stainless steel can show excellent corrosion resistance and is not easy to rust and damage. When baking some food containing acid or high salt, 316L stainless steel heating element can maintain good performance, and will not affect the service life because of the corrosion of food. Its high temperature resistance also makes it work stably in the case of high temperature baking to ensure the normal operation of the oven.

From the service life point of view, 316L stainless steel heating element is usually longer than 304 stainless steel heating element due to its excellent corrosion resistance and high temperature resistance. In the long-term use process, 316L stainless steel can better resist the erosion of the environment, reduce the replacement of heating elements caused by material damage, and reduce the cost of use and maintenance.

오븐 발열체:Other material features

In addition to metal, quartz element is also a heating element material that has been used in oven ovens. The main component of the quartz element is silicon dioxide, which has a high melting point and heat resistance, and can maintain relatively stable performance in high temperature environments. Its element diameter is large, and there is an air barrier between the internal heating wire and the external surface. This structure makes the power of a single quartz element larger than that of a single stainless steel heating element, so that a large amount of heat can be generated quickly when baking food and rapid baking can be achieved.

하지만, these characteristics of quartz elements also bring some disadvantages. Because its coefficient of thermal expansion is relatively large, when the temperature changes rapidly, it is easy to cause small deformation or crack due to thermal expansion and cold contraction, which affects its service life and performance. 게다가, as a glass material, the mechanical strength of the quartz element is relatively low, the texture is brittle, and in the process of transportation and use, once it is affected by collision or vibration, it is prone to damage, which will not only affect the normal use of the oven, but also may bring safety risks.

How to choose the Oven Heating element

오븐 발열체:Judge according to the use requirements

In the selection of oven oven heating element, first of all to clear their own use needs, different use scenarios and needs for different types of heating element.

For ordinary family daily baking, such as occasionally baking a cake, cookies or chicken wings, stainless steel heating element oven is a good choice. It has moderate price, stable performance, can meet the daily baking needs, and has a high cost performance. 게다가, the durability and corrosion resistance of the stainless steel heating element make it not easy to damage during long-term use, reducing the frequency and cost of replacing the heating element.

Professional baking enthusiasts have higher requirements for the quality and effect of baking, and they may frequently make a variety of complex baked goods, such as multi-layer cakes, delicate breads, 등. In this case, an oven heated by a light wave element may be more suitable for them. The light-wave element’s non-preheating function and excellent coloring effect can greatly improve the baking efficiency, make the baked food beautiful in color and taste better, and meet the pursuit of professional baking enthusiasts for baking quality.

For commercial baking, such as bakeries, cake shops, 등., it is necessary to consider the power, durability and stability of the heating element. Commercial baking usually requires the use of ovens for long periods of time and high intensity, so it is crucial to choose a heating element with high power and reliable quality. Due to its good high temperature resistance and stability, the stainless steel heating element can work stably in the commercial baking environment to ensure the normal operation of the oven and improve production efficiency. 게다가, its long service life can also reduce the cost of business operations.

오븐 발열체:Consider the performance parameters of the oven heating element

The performance parameters of the heating element are also the contents that need to be focused on when selecting, and these parameters directly affect the use effect and baking quality of the oven.

Power is an important parameter of the heating element, which determines the amount of heat generated by the heating element. In general, the greater the power, the faster the heating speed, the ability to raise the temperature in the oven to the set value in a shorter time. When choosing the heating element power, it should be determined according to the capacity and use needs of the oven. If it is a small capacity oven, choose a heating element with less power, which can meet the needs of baking and avoid energy waste; For large-capacity ovens, in order to ensure the heating effect and efficiency, it is necessary to choose a heating element with larger power.

The rate of heating is also a key factor. The fast heating speed can shorten the baking time and improve efficiency, while also maintaining the nutrition and taste of the food better. Different materials and types of heating elements, the heating speed is also different. 예를 들어, because of its unique heating method, light wave element can quickly generate a lot of heat, heating speed is relatively fast; Although the quartz element has a large power, the heating speed may not be ideal due to its low heat transfer efficiency.

Temperature uniformity is crucial to the quality of baked food. If the temperature of the heating element is not uniform, it will cause the food to be unevenly heated, and there will be some burnt and some uncooked. 가열 요소를 선택할 때, you can view the relevant introduction of the product or user evaluation to understand the performance of its temperature uniformity. Some high-quality heating elements will use special designs and processes, such as increasing the distribution density of heating wires, optimizing the shape of heating elements, 등., to improve temperature uniformity and ensure that food can be evenly heated.

오븐 발열체:Heating element maintenance and maintenance guide

Daily cleaning essentials

Keeping the heating element clean is an important link to ensure its normal operation and extend its service life. When cleaning the heating element, first ensure that the oven has been powered off and the heating element is completely cooled to avoid the risk of electric shock and burns.

For stainless steel heating elements, you can use a soft dry cloth or sponge dipped in an appropriate amount of neutral detergent, gently wipe the surface of the heating element dirt and food debris. Be careful not to exert too much force, so as not to scratch the passivation film on the surface of the heating element, affecting its corrosion resistance. If you encounter stubborn stains, you can soak the cleaner for a little while and then wipe. After cleaning, wipe the detergent residue with a clean wet cloth, and then dry with a dry cloth to ensure that there is no moisture residue on the surface of the heating element to prevent rust.

The cleaning method of quartz element and light wave element is similar, but due to the brittle texture of the quartz element, more care should be taken when wiping to avoid collision and excessive force resulting in damage to the quartz element. At the same time, avoid using cleaners or hard brushes containing scrub particles, so as not to scratch the surface of the quartz element, affecting its appearance and performance.

Precautions for use

When using the oven oven, it is necessary to strictly observe the use specifications to avoid damage to the heating element due to improper operation. First of all, to avoid dry burning, dry burning is one of the common causes of heating element damage. Before using the oven, make sure that the oven is filled with food that needs to be baked and that the oven door is closed tightly. If the oven is idling without food, the heat generated by the heating element cannot be effectively absorbed, which will cause the temperature of the heating element to be too high, accelerate its aging and damage, and may even cause safety accidents such as fire.

Also take care to prevent overload. Do not use multiple high-power electrical equipment at the same time, so as not to overload the circuit, affect the normal operation of the oven, and even damage the heating element. When choosing an oven, it is necessary to choose an oven with appropriate power according to the power consumption and actual needs of the family to ensure that it can operate stably within a safe range.

Also check the working condition of the heating element regularly. If it is found that the heating element is not heated evenly, does not heat, or appears smoke, odor and other abnormal conditions, it is necessary to stop using the oven in time, and contact professional maintenance personnel for inspection and maintenance. Do not disassemble and repair the heating element yourself, so as not to cause more serious damage or safety accidents.

Industry frontier: Innovation and development trends of oven heating elements

In the rapid development of science and technology today, the oven oven heating element is also constantly innovating to meet people’s growing cooking needs.

Energy-saving technology has become an important direction of heating element research and development. With the increasing global attention to energy issues, the research and development of energy-saving heating elements has become a hot spot in the industry. Some new heating elements use special materials and structural design, which can reduce energy consumption and achieve energy saving and environmental protection while ensuring the heating effect. By optimizing the material and shape of the resistance wire, it can improve its conductivity and reduce the loss of electric energy in the process of converting into heat energy. The use of efficient insulation materials to reduce heat loss and improve energy efficiency.

Intelligent temperature control technology has also brought new changes to the heating element. The emergence of intelligent temperature control technology makes the temperature control of the heating element more accurate.

Through the built-in temperature sensor and intelligent control system, the heating element can monitor the temperature in the oven in real time, and automatically adjust the heating power according to the preset temperature curve, ensuring that the food is baked at the most suitable temperature, avoiding the failure of food baking due to the temperature is too high or too low. Some high-end ovens are also equipped with smart chips, which can automatically adjust the working state of the heating element according to different ingredients and cooking modes, so as to achieve intelligent cooking.

In the future, with the continuous progress of science and technology, the oven oven heating element is expected to achieve greater breakthroughs in performance. Heating elements may heat faster, have better temperature uniformity, lower energy consumption, and there may even be smart heating elements that can automatically adjust heating parameters according to the type and weight of food. These innovations will further improve the performance of the oven, bring users a more convenient, efficient and healthy cooking experience, so that we can enjoy food at the same time, but also feel the charm of science and technology.

Choose Yuling electric oven heating element to open a new journey of delicious baking

Oven oven heating elements, as a key component in kitchen appliances, although seemingly insignificant, play a vital role in our culinary lives. It not only determines the heating efficiency and baking effect of the oven, but also is closely related to our diet health and quality of life.

When choosing a heating element, we need to consider many factors such as material, 유형, performance parameters and their own use needs. Different materials and types have advantages and disadvantages, only according to their actual situation to choose, in order to find the most suitable for their own heating element.

As a professional heating element manufacturer, Yuling Electric has many years of industry experience and advanced production technology. Our oven oven heating element is made of high quality materials and exquisite technology, with high temperature resistance, corrosion resistance, fast heating speed, good temperature uniformity and other advantages, can meet the needs of different users. 게다가, we also provide perfect after-sales service, so that you buy worry-free.

If you are struggling to choose a suitable Oven Heating element, you may wish to consider the products of Yuling Electric. We believe that choosing Yuling electric heating element is to choose quality, choose rest assured and choose delicious. Let’s use Yuling electric heating element together to open a new journey of delicious baking and bring more food enjoyment to family and friends!