Platinum-Rhodium thermocouples are a type of temperature sensor known for their high accuracy, stabilité, et large plage de température. Largement utilisé dans diverses applications industrielles, ces thermocouples sont un composant essentiel dans les environnements où des mesures précises de température sont essentielles. Cet article se penche sur leur composition, principes de travail, candidatures, avantages, and other relevant details to provide a comprehensive understanding of Platinum-Rhodium thermocouples.

Composition

Platinum-Rhodium thermocouples, often referred to as Type S, R., or B thermocouples, are made from a combination of platinum and rhodium. The three main types are:

- Type S (Platinum-10% Rhodium/Platinum): This type consists of one wire made of pure platinum and another wire made of a platinum-rhodium alloy containing 10% rhodium.

- Type R (Platinum-13% Rhodium/Platinum): Similar to Type S, but with a higher rhodium content of 13% in the alloy wire.

- Type B (Platinum-30% Rhodium/Platinum-6% Rhodium): This type features a wire made of platinum-30% rhodium and another wire made of platinum-6% rhodium.

| Conductor material | Taper | Grade | Spec. of protection tube(mm) | |||

| Longueur totale | Durée d'immersion | Diamètre | Material of protection tube | |||

| PtRh10-Pt | WRP | S | 300 350 400 450 550 650 900 1150 1300 | 150 200 250 300 400 500 750 1000 1100 | 8/10/16/25 | 99.9% Al2O3 ceramic |

| Pt-Rh30-Pt6 | WRP | B | 99.9% Al2O3 ceramic | |||

| PtRh13-Pt | WRQ | R. | 99.9% Al2O3 ceramic | |||

| Mini PtRh10-Pt | WRP | S | 150-1500 | 150-1500 | 99.9% Al2O3 ceramic | |

Working Principles

Thermocouples work based on the Seebeck effect, which states that a voltage is generated when there is a temperature difference between two dissimilar metals or semiconductors. In Platinum-Rhodium thermocouples, the junction of the platinum and platinum-rhodium wires generates a voltage proportional to the temperature difference between the hot junction (where the measurement is taken) and the cold junction (reference point). This voltage is then measured and converted into a temperature reading.

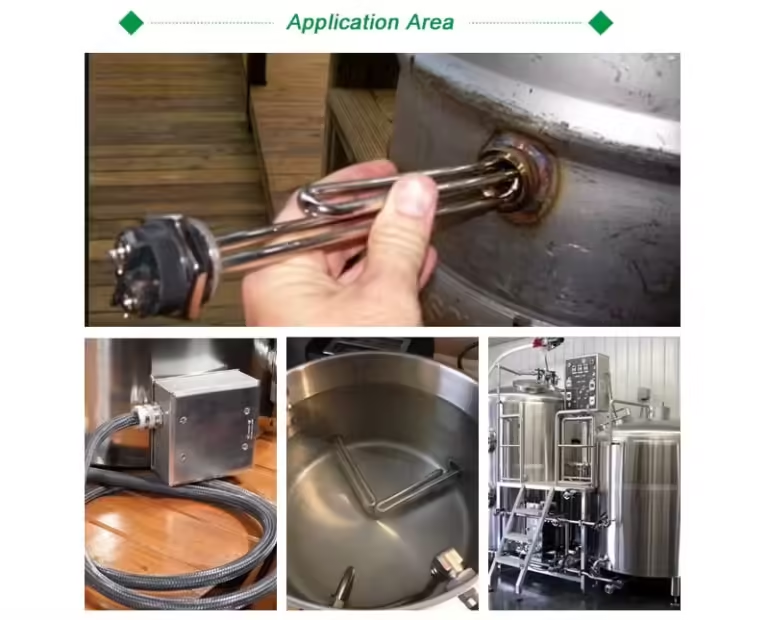

Applications

Platinum-Rhodium thermocouples are used in various high-temperature applications due to their ability to measure temperatures up to 1800°C (3272°F). Some common applications include:

- Aerospace: Used in jet engines and other high-temperature components to ensure safe and efficient operation.

- Metal Processing: Essential for monitoring and controlling temperatures in processes like melting, casting, and heat treatment.

- Fabrication de verre: Used to measure temperatures in glass furnaces and kilns to maintain product quality.

- Research Laboratories: Employed in scientific research requiring precise temperature measurements in high-temperature environments.

Avantages

Platinum-Rhodium thermocouples offer several advantages over other types of thermocouples:

- High Accuracy: These thermocouples provide highly accurate temperature measurements, making them ideal for applications requiring precise control.

- Stability: They exhibit excellent stability over long periods, ensuring consistent performance and reducing the need for frequent recalibration.

- Wide Temperature Range: Capable of measuring temperatures from 0°C to 1800°C (32°F to 3272°F), they are suitable for a wide range of high-temperature applications.

- Corrosion Resistance: The platinum and rhodium materials are highly resistant to corrosion and oxidation, extending the lifespan of the thermocouple in harsh environments.

Limitations

Despite their numerous advantages, Platinum-Rhodium thermocouples have some limitations:

- Coût: The high cost of platinum and rhodium makes these thermocouples more expensive than other types, such as Type K or Type J thermocouples.

- Fragility: The wires in Platinum-Rhodium thermocouples are relatively fragile and can be damaged easily if not handled with care.

Conclusion

Platinum-Rhodium thermocouples are indispensable tools in industries and research fields that require precise and reliable high-temperature measurements. Their composition of platinum and rhodium provides exceptional accuracy, stabilité, and resistance to corrosion, making them ideal for demanding applications. While they come at a higher cost and require careful handling, their benefits often outweigh these drawbacks, ensuring they remain a preferred choice for professionals in various high-temperature environments. Understanding the intricacies of Platinum-Rhodium thermocouples can help you make informed decisions when selecting the right temperature measurement solution for your needs.

The Platinum-Rhodium Thermocouples we purchased have exceeded our expectations in both accuracy and reliability. Highly recommend!

We’ve been sourcing these thermocouples for our industrial applications, and they have been incredibly consistent and durable.

Fantastic performance! These thermocouples offer precise temperature readings which are crucial for our manufacturing process.

Our team is extremely satisfied with the quality and service associated with these Platinum-Rhodium Thermocouples. Perfect for our needs.

Produit exceptionnel! The durability and precision of these thermocouples have significantly improved our operational efficiency.