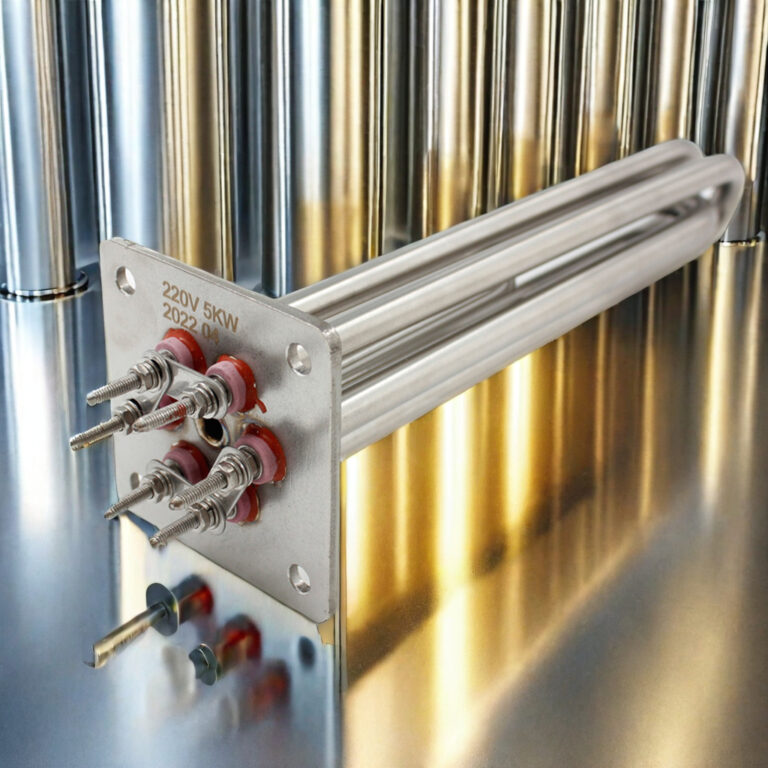

Definition and basic principle of electric fin tube heater

A electric fin tube heater is a specially designed heating device that increases the heat transfer efficiency by increasing the surface area. The core principle is to use the fin structure to expand the contact area with the heated object, so as to more effectively dissipate and transfer heat. Fin heater designs usually include one or more heating elements that are fixed to fins with high thermal conductivity, usually aluminum or copper.

Finned heaters have significant advantages over conventional heaters. While conventional heaters rely on direct contact or convection to transfer heat, fin heaters enable more efficient heat transfer through their extended surface area. This design not only improves the heating efficiency, but also can achieve the same heating effect at a lower operating temperature, thus extending the service life of the equipment.

The design of the fin plays a crucial role in the performance of the electric fin tube heater. The shape, size and arrangement of the fins will affect its heat dissipation effect. Common fin designs include straight fins, spiral fins and corrugated fins. Different types of fin heaters can be used for different application scenarios. For example, straight fin heaters are suitable for general industrial heating needs, while spiral fin heaters are more suitable for environments that require efficient heat dissipation.

Fin heaters are widely used in many fields such as industry, commerce and home. Its efficient heat transfer capability makes it ideal for many heating applications. From air conditioning systems to industrial furnaces, from water heaters to drying equipment, fin heaters are used in a wide range of applications.

| Technical Details | |

| Construction Diameter | 8MM 10MM 12MM 14MM 16MM 18MM 20MM. etc |

| Tube Material | stainless steel 304/321/316/310S,Incoloy 800 840 |

| Ppwer Tolerance | Tolerance±10% |

| Use of Alloys | Suitable for heater tube AISI 304 in water or humid enviroment max temperature up to 170°C. In air max 220°C |

| Thread | M12 M14 M16 M18 |

| Watt Density | Tube watt density of 30 watts sq in-suitable for many uses |

| Custom | Custom configurations, lengths, watts, volts available |

Fin heaters play a vital role in various fields, and their applications range widely, covering many aspects of industry and civil. Specific application scenarios include but are not limited to industrial processing, air conditioning systems, HVAC engineering and home heating.

In the field of industrial processing, fin heaters are often used to control and maintain the temperature of the processing environment. For example, in food processing plants, fin heaters can effectively provide a stable heat source, ensuring that food is processed and stored at the right temperature. At the same time, in the chemical industry, fin heaters play a key role in temperature control during chemical reactions, and their efficient heat transfer performance can significantly improve production efficiency.

Fin heaters are also widely used in air conditioning systems and HVAC projects. Air conditioning systems need to heat or cool the air, and fin heaters, through their large surface area design, can quickly and efficiently heat the air, thereby improving the energy efficiency of the entire system. Similarly, in HVAC engineering, fin heaters are used to heat water or other fluids to ensure warmth and comfort inside the building. These areas require stable operation and long life, and fin heaters are ideal because of their durability and efficiency.

Home heating is another important application scenario for electric fin tube heaters. As people’s requirements for quality of life increase, the safety and energy efficiency of household appliances become particularly important. With their uniform heat distribution and efficient energy consumption, fin heaters are able to provide continuous warmth to the home during the cold season, while they are also designed with safety in mind to avoid overheating and fire risks.

In general, electric fin tube heaters have been widely used in many fields due to their excellent performance and wide applicability. Whether it is industrial processing or home heating, fin heaters are efficient, durable and safe to meet the specific needs of a variety of scenarios.`

How to select and maintain electric fin tube heater

Choosing the right electric fin tube heater is essential to ensure its long-term efficient operation. There are several key factors to consider, the first being power. The power of the fin heater must match the required heating demand. Too high or too low a power will affect the heating efficiency and energy efficiency. Often, looking at the specifications of your device or consulting a professional can help you determine the right power.

Material is also an important consideration when choosing a electric fin tube heater. Different materials behave differently in different environments. For example, stainless steel fin heaters perform well in wet environments, while carbon steel fin heaters are suitable for dry environments. In addition, specific applications may require special materials that are resistant to corrosion or high temperatures.

In terms of design, the shape and size of the electric fin tube heater should also match the installation environment. The compact design is suitable for tight Spaces, while the larger fin area provides higher heat transfer efficiency. Make sure you choose a design that fully meets your installation and use needs.

Maintaining the electric fin tube heater is also an important part of ensuring its stable operation. Regular cleaning of the fin surface prevents the accumulation of dust and dirt, thus maintaining a good heat transfer effect. Check electrical connections and fasteners regularly to make sure they are not loose or damaged. In addition, check the temperature control system of the heater regularly to ensure that it is working properly to avoid overheating or undercooling problems.

In general, the selection and maintenance of fin heaters requires a combination of factors. Through proper selection and regular maintenance, you can ensure that the electric fin tube heater remains in the best condition in a variety of application scenarios, providing lasting and efficient heating results.