Silicon Molybdenum Rod 1700U Type Electric Heating element High-temperature Furnace Denture Zirconia Sintering Furnace Heating

Silicon Molybdenum Rod 1700U Type Electric Heating element High-temperature Furnace Denture Zirconia Sintering Furnace Heating

Description

Silicon Molybdenum Rod 1700U Type Electric Heating element High-temperature Furnace Denture Zirconia Sintering Furnace Heating

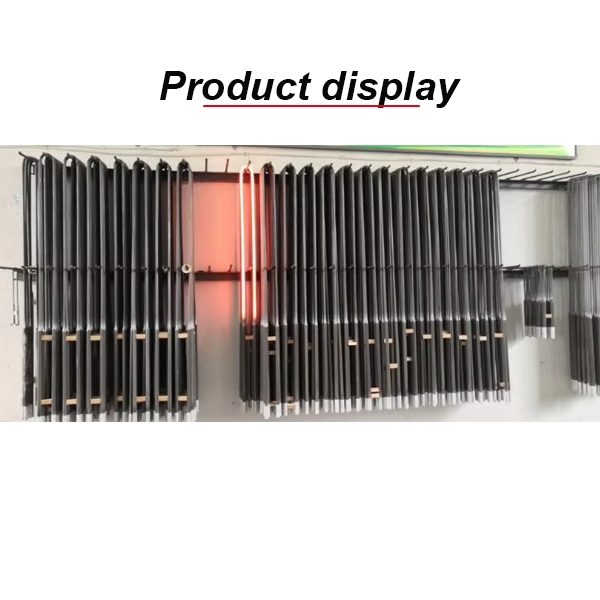

Product Description

Silicon Molybdenum Rod 1700U Type Electric Heating element High-temperature Furnace Denture Zirconia Sintering Furnace Heating

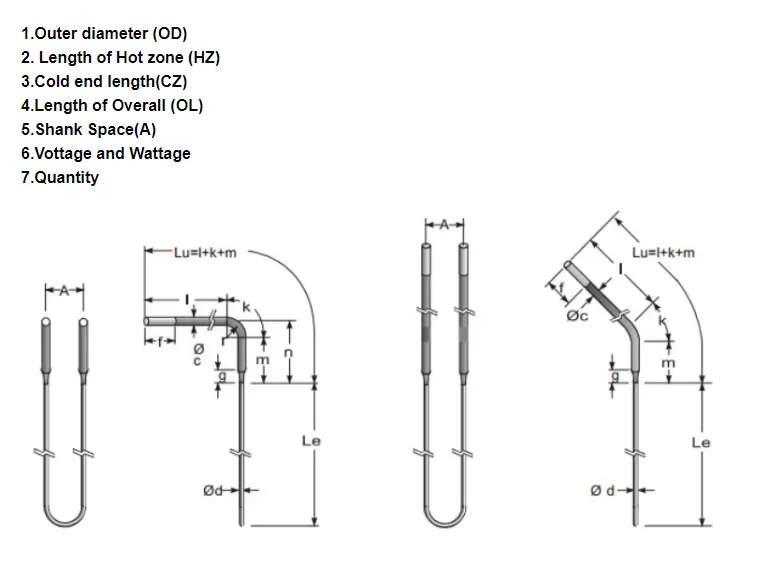

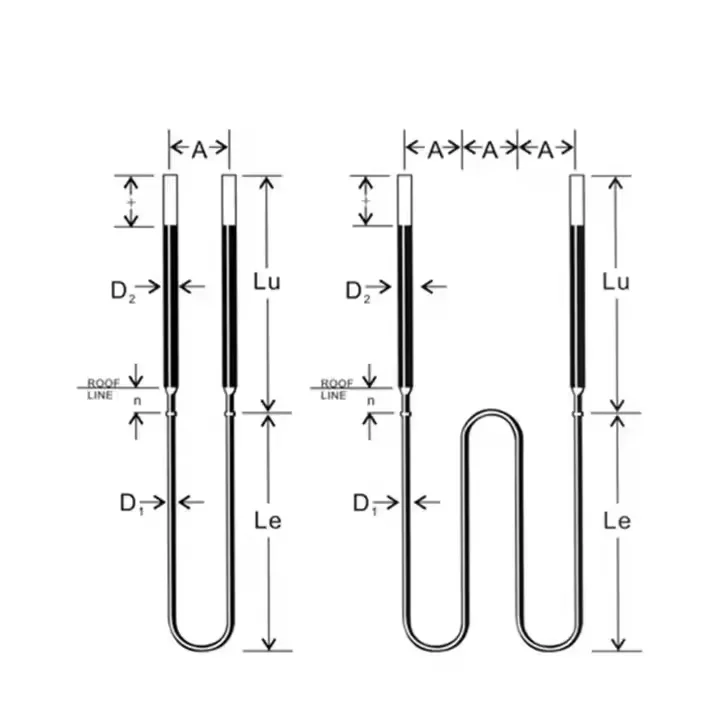

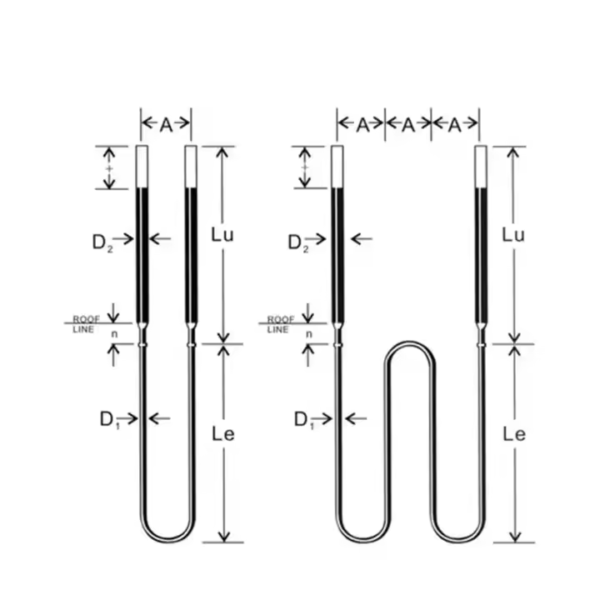

Silicon molybdenum rods come in a wide variety of specifications. Common ones include diameters of 3mm, 4mm, 5mm, 6mm, 7mm, 9mm,12mm, etc. The corresponding thickened parts have diameters of 6mm, 8mm, 10mm, 12mm, 14mm, 18mm, 24mm, etc. The length can also be flexibly customized according to actual needs. Meanwhile, the product shapes not only include the conventional straight rods, but also special designs such as U-shaped rods, W-shaped rods, and curved right-angle rods, and even include molybdenum disilicide straight-through tubes and thermocouple protection tubes

Specification

Product Name | Silicon molybdenum rod |

Material | Molybdenum Disilicide |

Refractoriness (Degree) | 1770°< Refractoriness< 2000° |

Model Number | Straight/U/W/L |

Volume Density | 5.5-5.6 g/cm3 |

Bend Strength | 15-25 kg/cm2 |

Diameter | 3/6mm 4/9mm 5/10mm 6/12mm 7/14mm 9/18mm |

Thickness | customized |

Delivery Date | 7-15 days |

Voltage | 220V/380V/Customized |

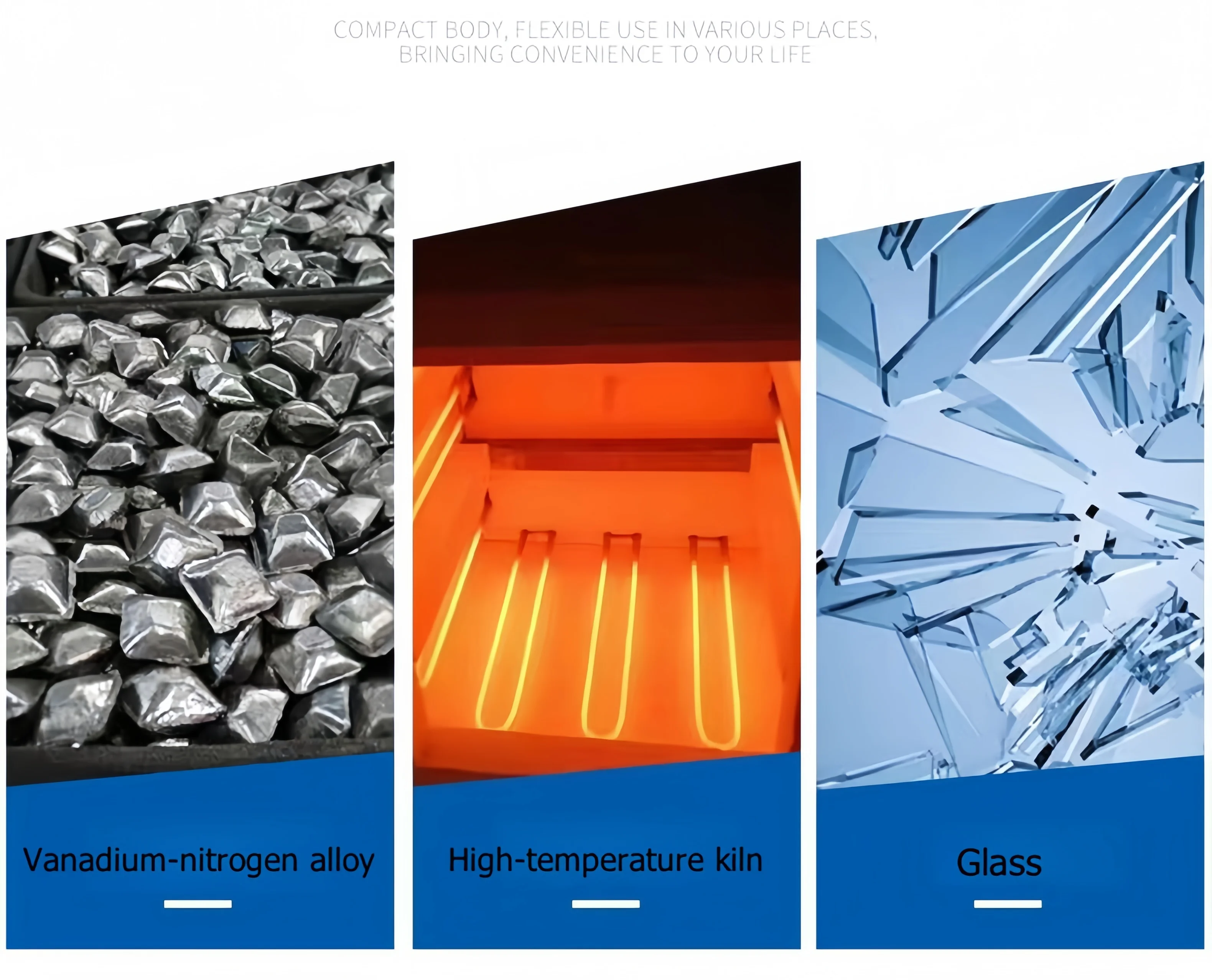

Application | Heating elements in industrial kilns for magnetic materials, glass, ceramics, etc |

Our Advantages

Precautions:

1.Silicon-molybdenum rod electric heating elements are hard and brittle. During transportation, acceptance and installation, they should be handled with care and stored in a dry and well-ventilated place to prevent oxidation and deliquescence at the aluminum-sprayed area.

2. When selecting silicon-molybdenum rod electric heating elements, it is necessary to ensure that the heating length of the elements does not exceed the width of the furnace chamber. If the heating part extends into the furnace wall, it is easy to damage the furnace wall.

3. Silicon-molybdenum rods should not be used for a long time within the range of 400°C to 700°C; otherwise, the components will powderize due to the strong oxidation effect at low temperatures.

4. Silicon-molybdenum rod resistors generally do not change with the length of usage time, so new and old components can be used in combination.

1.Silicon-molybdenum rod electric heating elements are hard and brittle. During transportation, acceptance and installation, they should be handled with care and stored in a dry and well-ventilated place to prevent oxidation and deliquescence at the aluminum-sprayed area.

2. When selecting silicon-molybdenum rod electric heating elements, it is necessary to ensure that the heating length of the elements does not exceed the width of the furnace chamber. If the heating part extends into the furnace wall, it is easy to damage the furnace wall.

3. Silicon-molybdenum rods should not be used for a long time within the range of 400°C to 700°C; otherwise, the components will powderize due to the strong oxidation effect at low temperatures.

4. Silicon-molybdenum rod resistors generally do not change with the length of usage time, so new and old components can be used in combination.

Application

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Product packaging

Product Packaging Solutions

1.Our services include individual unit packaging with optional labeling to streamline operations and reduce time costs.

2.We provided fumigated solid wood pallets for heavy-duty exports and durable plywood crates for lighter loads, exempt from fumigation.

3.All solutions adhere to international trade standards, including certification for shipments to the US, Canada, and the EU, ensuring seamless customs clearance and pest control compliance.

2.We provided fumigated solid wood pallets for heavy-duty exports and durable plywood crates for lighter loads, exempt from fumigation.

3.All solutions adhere to international trade standards, including certification for shipments to the US, Canada, and the EU, ensuring seamless customs clearance and pest control compliance.

Our core competencies:

1.Vertical Manufacturing Expertise:The factory which we cooperated with operating professional production facilities, they maintain full control over Research and development. This vertical integration ensures stringent quality compliance (ISO 9001, CE,CQC,Rohs, UL) and enables competitive pricing without intermediaries.

2.Dual-Channel Procurement Solutions:Direct OEM Services, Customize heating systems and linear slot diffusers to meet project-specific airflow and thermal requirements.

3.Direct OEM Services: Customize heating systems and linear slot diffusers to meet project-specific airflow and thermal requirements.

4.Technical Partnership Model:Beyond transactional engagements, we provide ventilation system design and Energy efficiency audits for heating solutions,multilingual after-sales technical support.

5.Innovation and Sustainability:Investing 8% of annual revenue in R&D to be committed to creating better new products.

2.Dual-Channel Procurement Solutions:Direct OEM Services, Customize heating systems and linear slot diffusers to meet project-specific airflow and thermal requirements.

3.Direct OEM Services: Customize heating systems and linear slot diffusers to meet project-specific airflow and thermal requirements.

4.Technical Partnership Model:Beyond transactional engagements, we provide ventilation system design and Energy efficiency audits for heating solutions,multilingual after-sales technical support.

5.Innovation and Sustainability:Investing 8% of annual revenue in R&D to be committed to creating better new products.

Certifications

FAQ

1. who are we?We are based in Jiangsu, China, start from 2021,sell to North America(90.00%),Domestic Market(10.00%). There are total about 11-50 people in our office.2. how can we guarantee quality?Always a pre-production sample before mass production;Always final Inspection before shipment;3.what can you buy from us?Heating Element, Ventilation Products, Thermocouple4. why should you buy from us not from other suppliers?we have passed the industry qualification certification to protect the product quality. We provide one-stop procurement services to reduce the procurement cost for customers.5. what services can we provide?Accepted Delivery Terms: FOB,EXW,DDP;Accepted Payment Currency:USD;Accepted Payment Type: T/T,L/C,D/P D/A;Language Spoken:English,Chinese,French

You must be logged in to post a review.

Reviews

There are no reviews yet.