Electric Power Cable Heat Trace Cable Heating Tape 500C High Temperature Fiberglass Braid Heating Belt for Pipeline

Electric Power Cable Heat Trace Cable Heating Tape 500C High Temperature Fiberglass Braid Heating Belt for Pipeline

Description

Electric Power Cable Heat Trace Cable Heating Tape 500C High Temperature Fiberglass Braid Heating Belt for Pipeline

Product Description

Fibergalss Electric Heating Cable

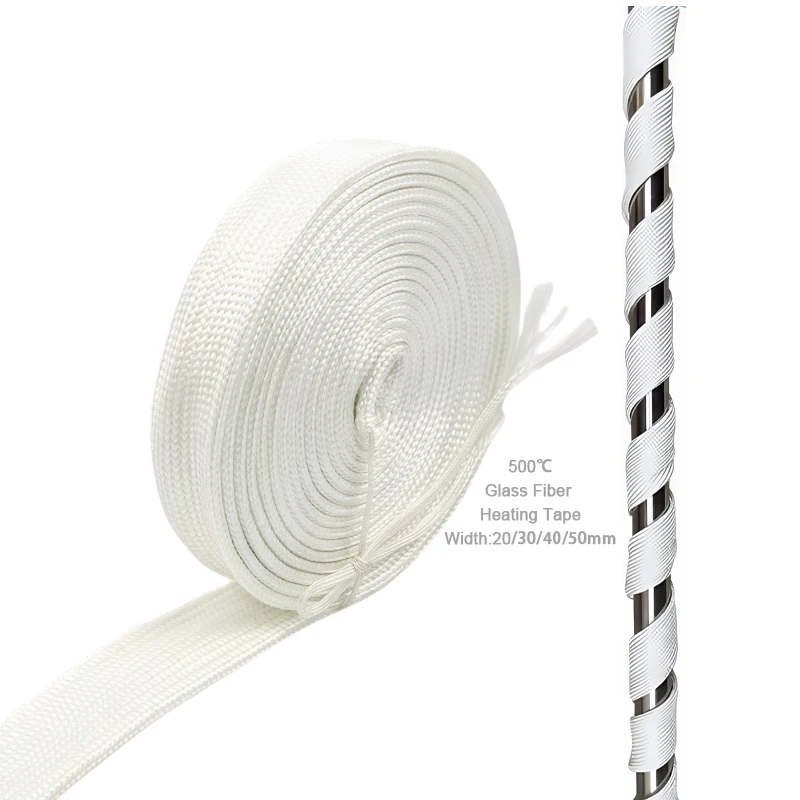

Fiberglass electric heating cable is suitable for heating and heat preservation of tanks, tubes, tanks and other containers ofvarious industrial equipments. It is mainly composed of electrothermal materials and insulating materials. The electrothermalmaterials are nickel-chromium alloy belts, which have fast heat generation and high thermal efficiency.

Long service life, the insulation material is multi-layer alkali-free glass fiber, with good temperature resistance and reliableinsulation performance. The utility model has the advantages of soft structure, can be directly wound on the surface of the heatedpart when used, and has uniform temperature, simple installation, convenient use, safety and reliability.

Specification

Structural Performance(1) It is mainly composed of nickel-chromium alloy wires and insulating material, and has fast heating speed, high heat efficiency and long service life.(2) Alkali-free glass fiber core rack is wound with electric heating wires, fiberglass is used as main insulation, the heatresistance performance is excellent, and the insulation performance is reliable.(3) It has great flexibility, and can be directly wound on a to-be-heated device, with good contact and uniform heating.Note: fiberglass heating cable do not have the functions of waterproof and moistureproof .

Product | Voltage(V) | Wattage(W) | Width(mm) | Insulation Resistance | Maximum Temperature |

RDG–1 | 220 | 100 | 10-30 | >2MΩ | ≤500℃ |

RDG–2 | 220 | 200 | 10-30 | ||

RDG–3 | 220 | 300 | 10-30 | ||

RDG–4 | 220 | 400 | 10-30 | ||

RDG–5 | 220 | 500 | 10-30 | ||

RDG–6 | 220 | 600 | 10-30 | ||

RDG–7 | 220 | 700 | 10-30 | ||

RDG–8 | 220 | 800 | 10-30 | ||

RDG–9 | 220 | 900 | 10-30 | ||

RDG–10 | 220 | 1000 | 10-30 |

Installation Instructions

Step 1: Pipe Surface PreparationPrepare surface to be heated: Wipe the surface making sure there is no foreign material, like liquid, on the surface. Foreignmaterial inhibits heat transfer and liquid can damage select models of heating tape (i.e. HighTemperature Heating Tapes).Make a visual inspection of heating tape: We recommend that you replace the heating tape if it becomes torn or damaged. Damaged heating tape is a safety hazard and will not operate correctly.Step 2: Heating Tape Installation (wrap)Heating tape can be installed on nearly any surface due to its flexibility. Spiral wrap the heating tape onto the surface to beheated so that the length of one entire side of the heating tape is in full contact with the surface .The distance between spiral wraps is dependent on the uniformity requirements and the amount of available heating tape. A minimum distance of 1/8” is required between spiral wraps to avoid damage to the heating tape.Attach the heating tape to the surface by either using built-in tie straps, high-temperature adhesive tape or mechanical clamping devices that will not cause damage to the heating tape.Ensure the heating tape is not kinked, twisted, or hanging free from the surface.Do not overlap heating tape on itself.This can cause damage to the heating tape due to overheating.Step 3: Connecting Your Heating Tape to a Temperature Controlling DeviceYour heating tape must be connected to an external temperature control device. Ensure your temperature controller is protected by a properly sized circuit breaker or fuse. Use of a ground fault circuit interrupter is highly recommended and may be required for your installation.For proper temperature control, secure a thermocouple, RTD, or other sensing device with one strip of adhesive tape so that it is in close proximity to the heater to prevent overheating.

Packing & Delivery

FAQ

1. who are we?We are based in Jiangsu, China, start from 2010,sell to Oceania(50.00%),North America(30.00%),South America(10.00%),Southern Europe(10.00%). There are total about 11-50 people in our office.2. how can we guarantee quality?Always a pre-production sample before mass production;Always final Inspection before shipment;3.what can you buy from us?Cartridge Heater/Cast-In Heater/Circulation Heater/Enginee Block Heater/Open Coil Heater, Finned Heater/Strip Heater/Heating Element4. why should you buy from us not from other suppliers?1.More than 40 years experence

2.UL CE RoHS CQC ISO9001:2008

3.The R&D team

4.Provide test report

5.Support product design5. what services can we provide?Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDU,Express Delivery;Accepted Payment Currency:USD,EUR,CNY;Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;Language Spoken:English,Chinese,French

2.UL CE RoHS CQC ISO9001:2008

3.The R&D team

4.Provide test report

5.Support product design5. what services can we provide?Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDU,Express Delivery;Accepted Payment Currency:USD,EUR,CNY;Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;Language Spoken:English,Chinese,French

You must be logged in to post a review.

Reviews

There are no reviews yet.